To Understand

Your Project Goals and Outputs

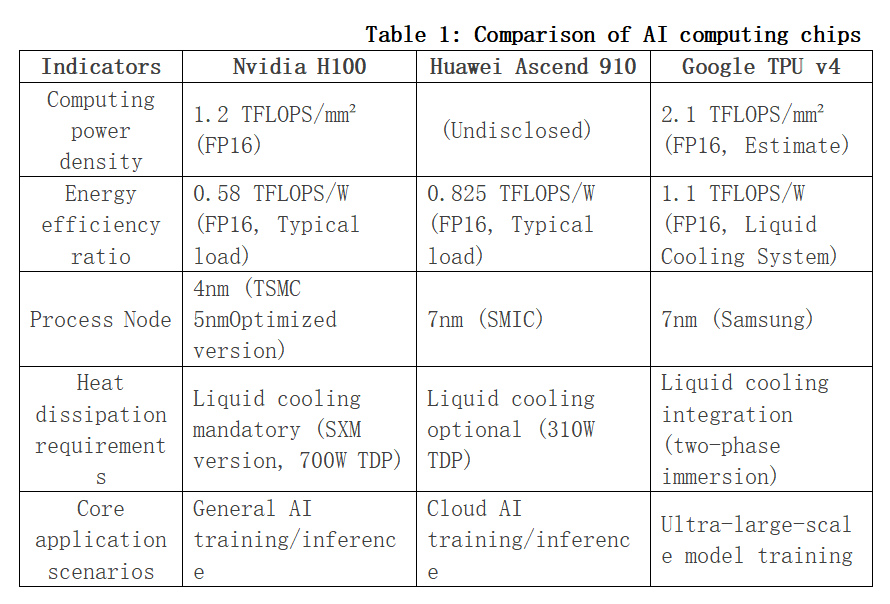

On the path toward Exascale AI computing power, Huawei's CloudMatrix 384 Super Node and NVIDIA's GB200 NVL72 cluster have emerged as two globally prominent technological peaks. They not only represent different hardware integration capabilities but also profoundly reveal two fundamental philosophies for building supercomputing systems.

One is metaphorically described as a "sustained high fever," facing the ultimate thermal challenge of densely packed, steady-state heat dissipation from 384 chips operating at full throttle. The other is likened to "intermittent epileptic seizures," requiring the taming of intense, pulsed heat flows generated when 72 top-tier GPUs work in synchrony. These two different "maladies" ultimately lead to entirely distinct "prescriptions"—namely, thermal solutions—and provide us with a clear view of two core engineering philosophies: deterministic systems engineering versus agile ecosystem innovation. For every company in the supply chain involved, understanding this duel is key to defining their future role.

1-The Root of Core Differences – The "Malady" Determines the "Prescription"

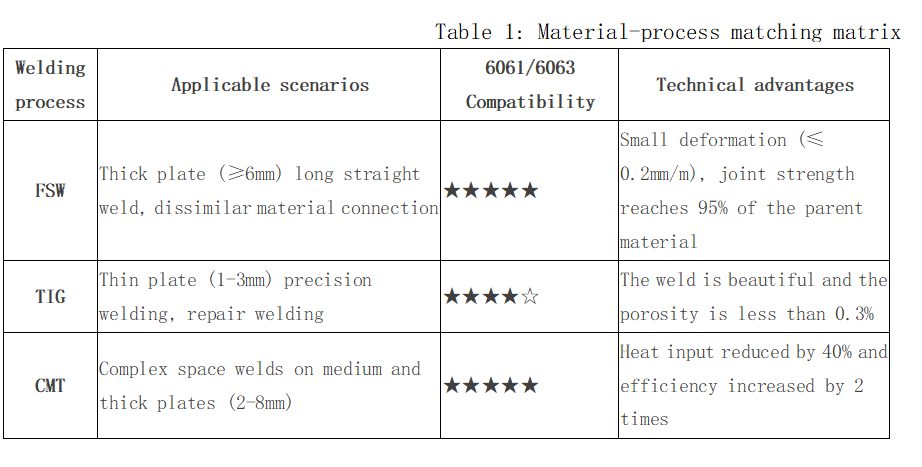

From the outset of design, Huawei and NVIDIA embarked on different paths, directly shaping their distinct thermal source characteristics:

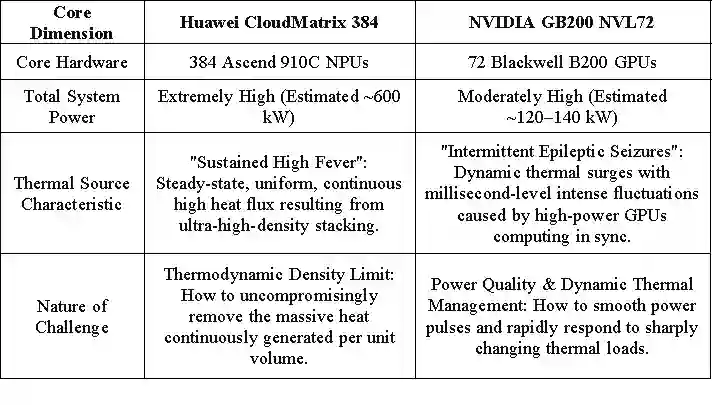

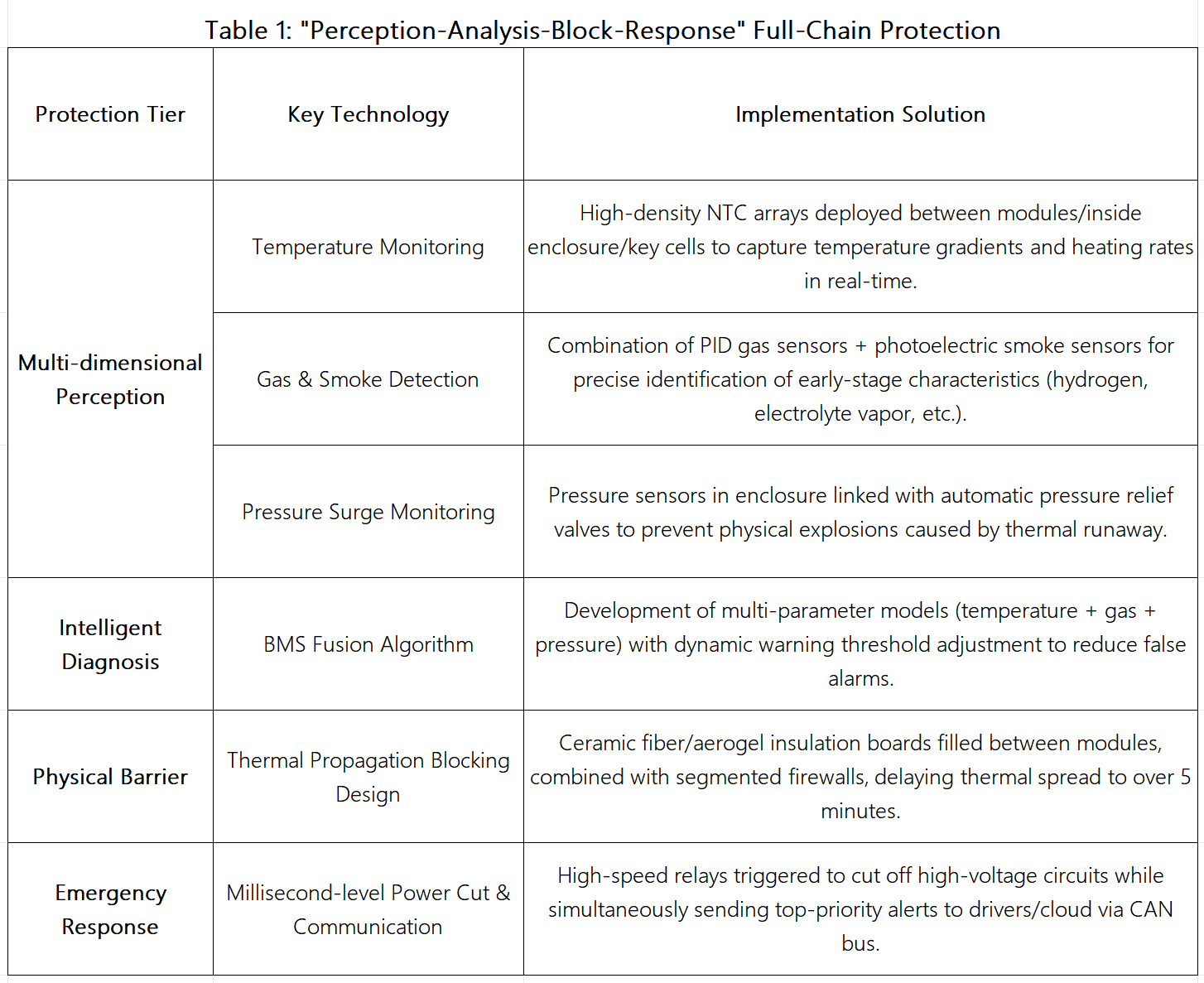

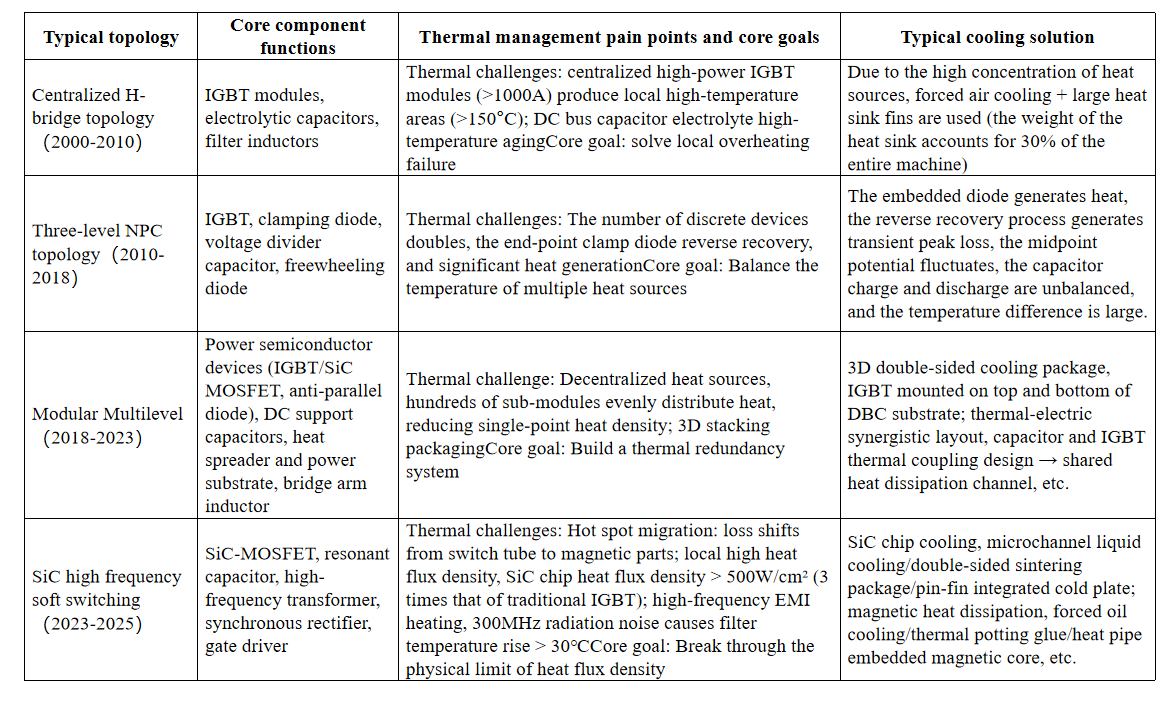

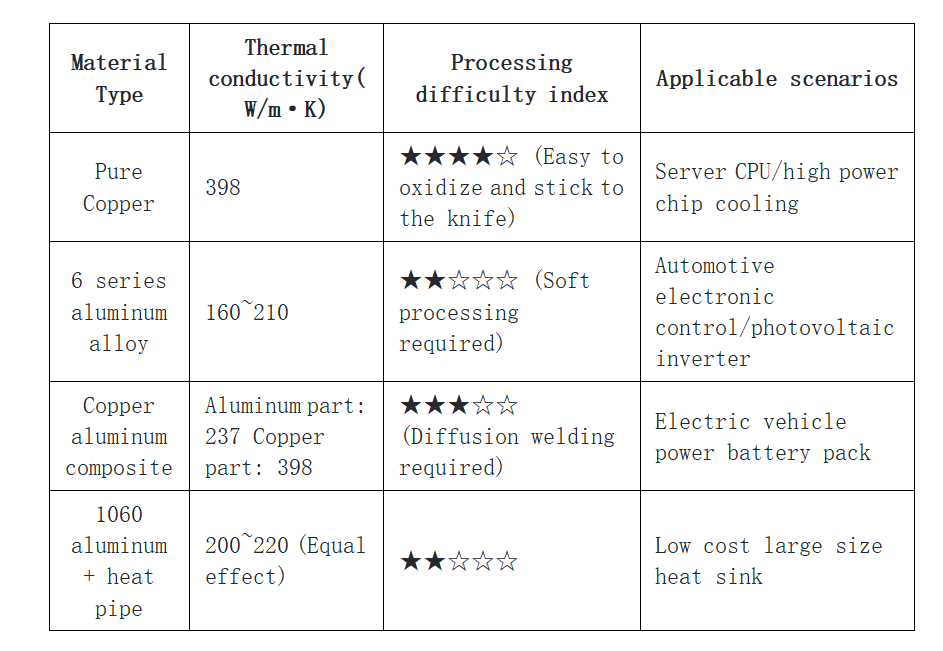

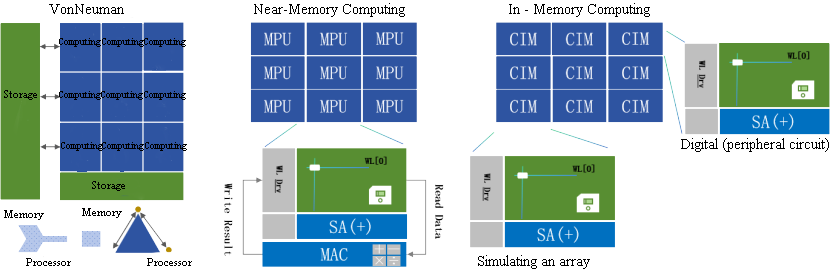

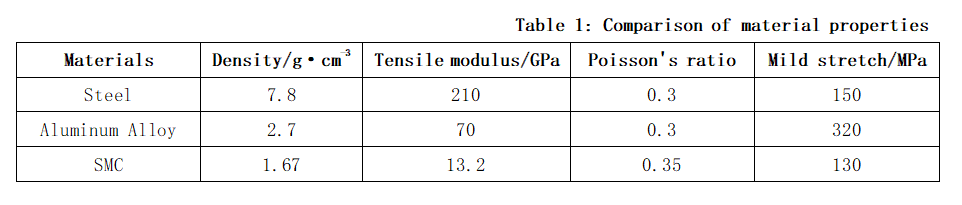

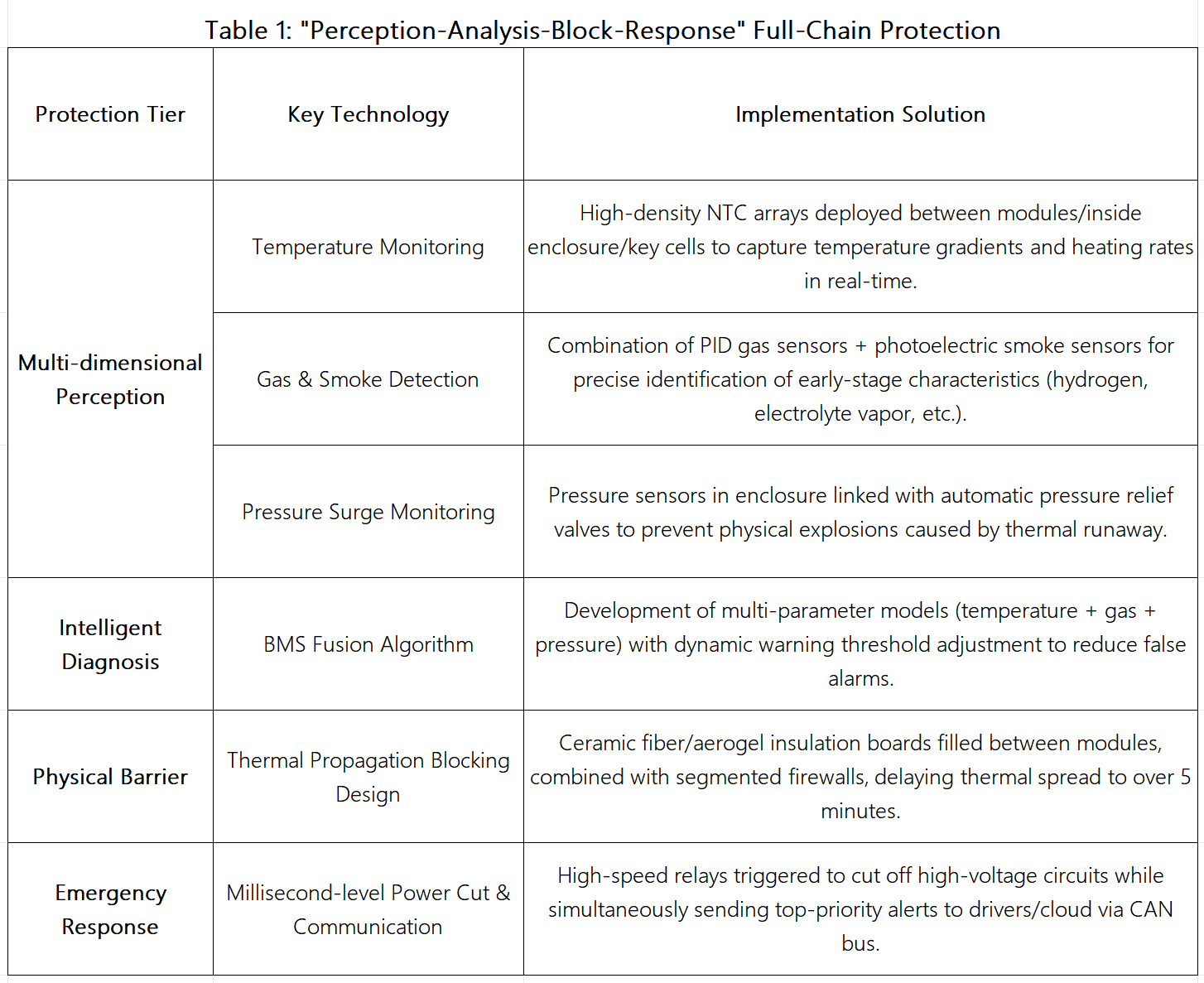

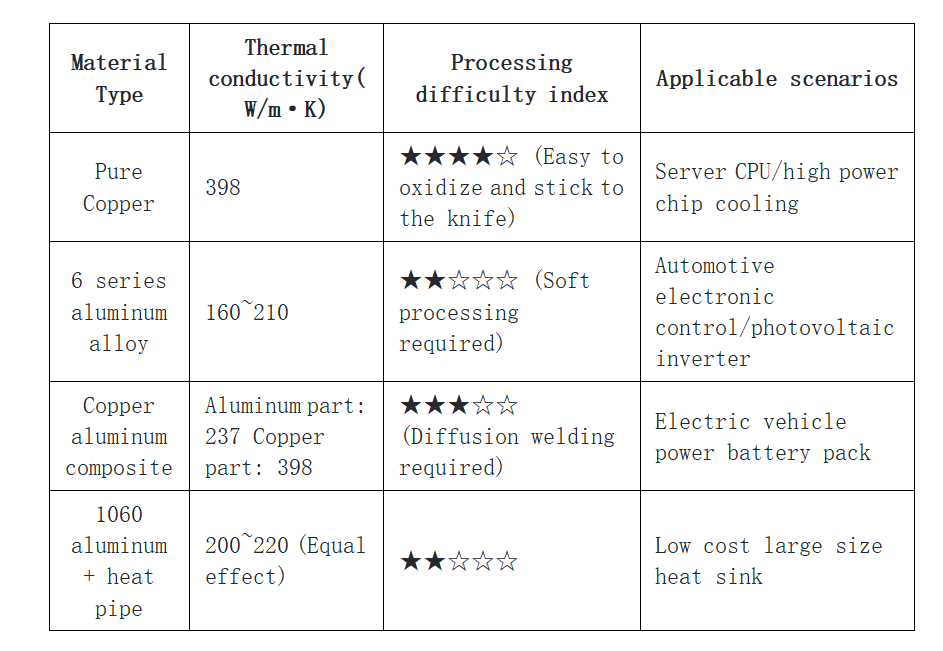

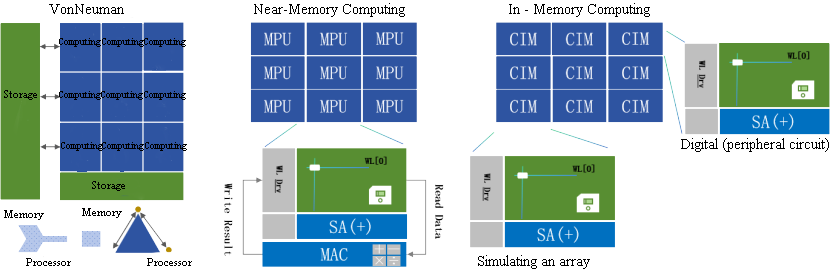

Table 1: Comparison of Thermal Source Characteristics Between Two Technical Approaches

The difference between this "sustained high fever" and "intermittent epileptic seizures" is by no means accidental. It reflects Huawei's choice as a challenger to focus on total system performance, pushing the limits of computing density within a single cabinet at all costs, while NVIDIA, as the leader, faces the task of building an ecosystem that can efficiently collaborate and be widely adopted while maintaining an absolute performance advantage per chip.

2- The Materialization of Engineering Philosophy – Two Liquid Cooling Paths

The two distinct design philosophies are most vividly embodied in their respective liquid cooling solutions, shaping the complete technology stack from the chip to the data center room.

a. Huawei: The Liquid Cooling Practice of Deterministic Systems Engineering

This is a top-down design philosophy born for system-level deterministic goals. Its core lies in treating thermal management as a crucial part of the infrastructure, achieving it through globally integrated, highly reliable engineering, rather than treating it merely as a supporting component.

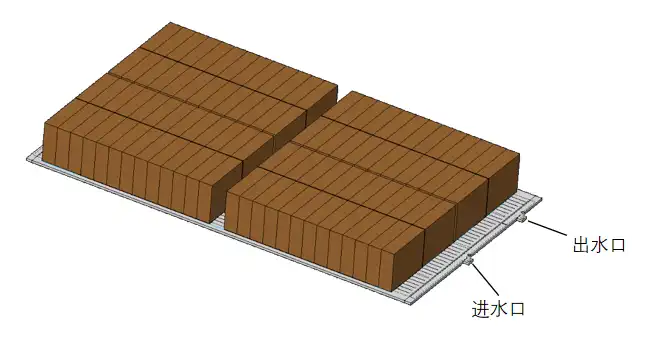

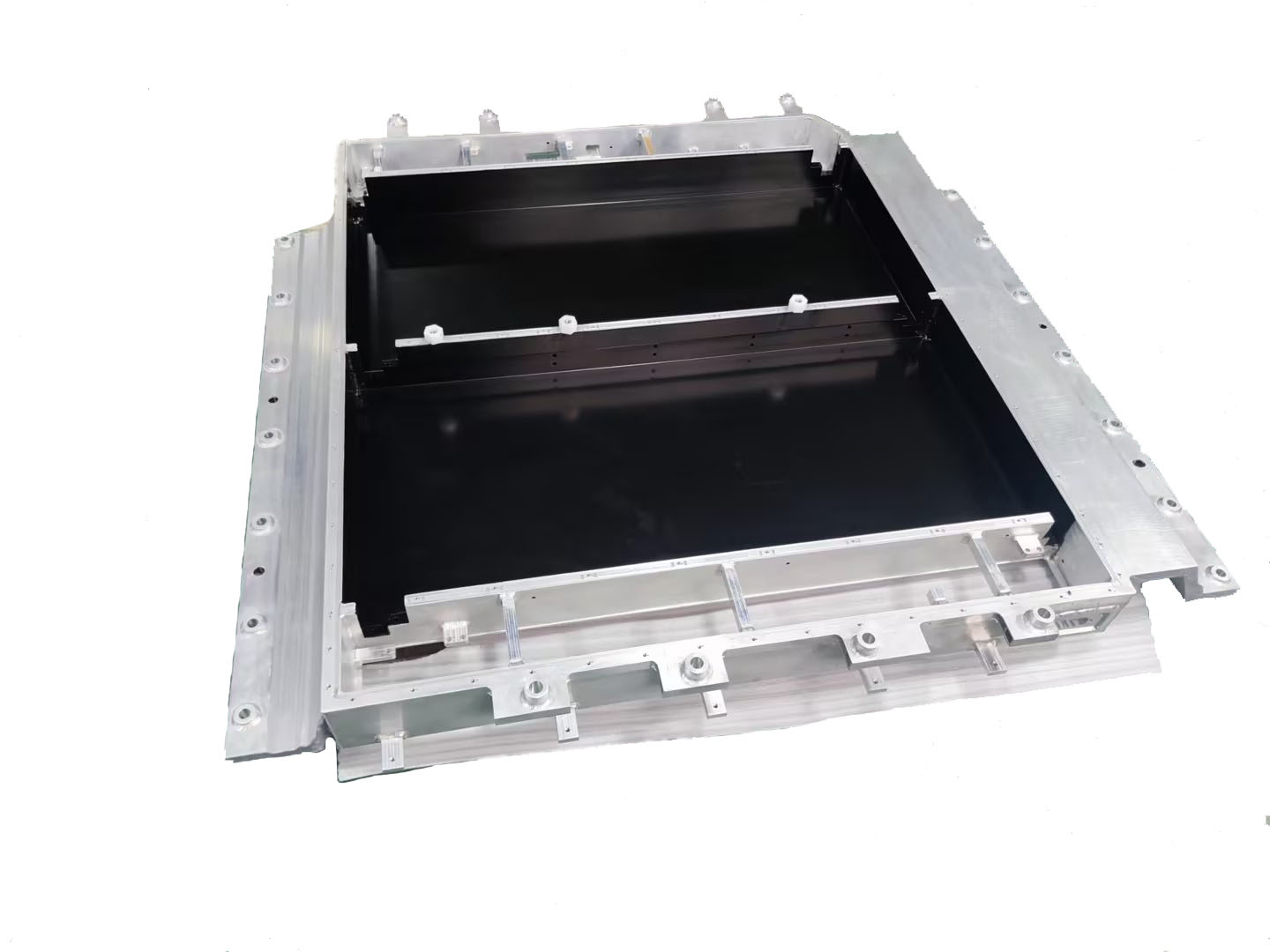

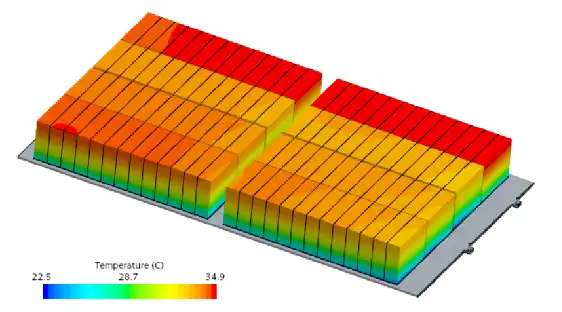

Figure 1: Huawei Ascend 384 Super Node

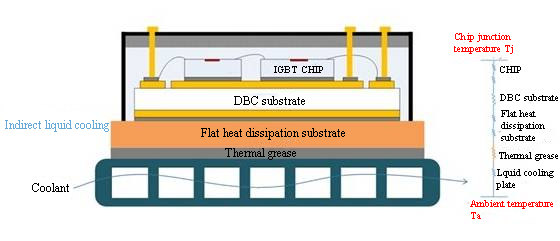

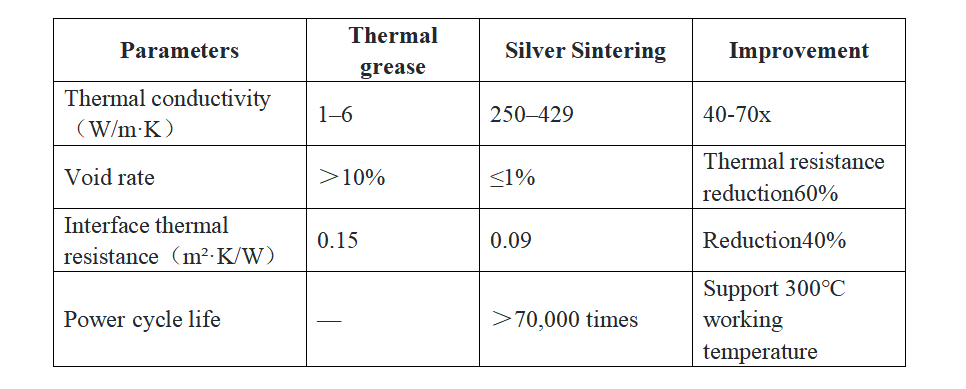

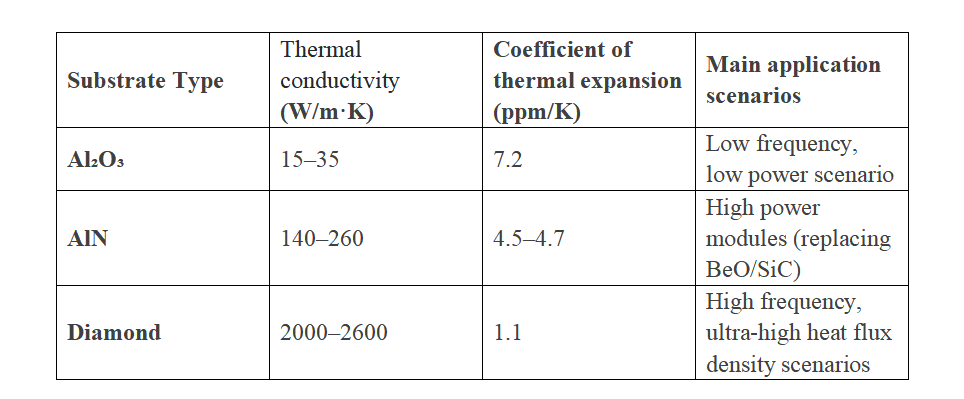

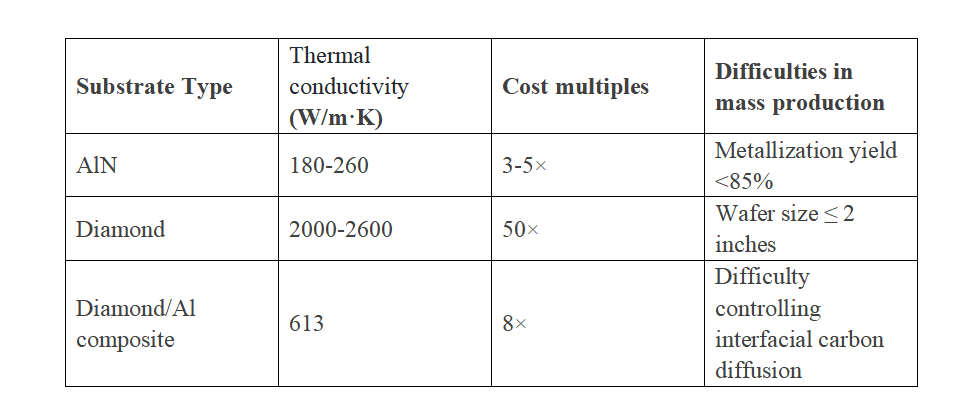

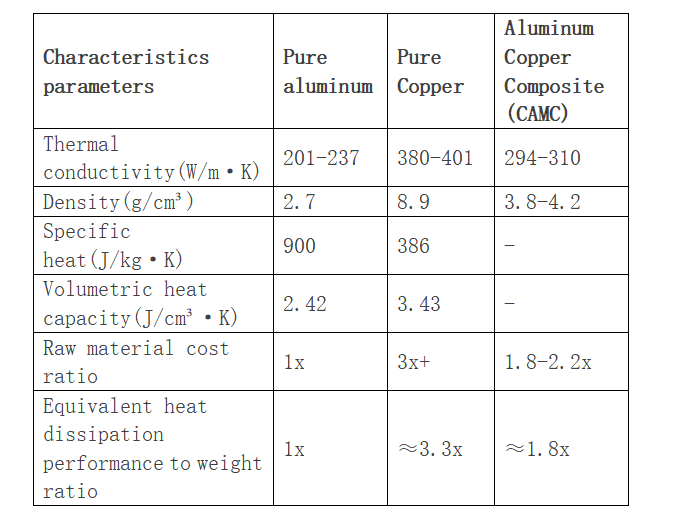

· Chip-level Precision Engineering and Reliable Connection: To ensure efficient heat transfer from the chip to the cold plate, Huawei focuses on engineering optimization of interface materials. While public information shows its advanced patent reserves in this field (e.g., using high-sphericity silicon carbide fillers), its specific implementation within the super node remains undisclosed. It is certain that its solution inevitably pursues extremely low interfacial thermal resistance and long-term reliability to meet the "sustained high fever" challenge.

· System-level Redundancy and Intelligent Control: Adopts redundant designs, such as ring-shaped liquid supply, and develops in-house Liquid Cooling Thermal Management Units (TMUs) as the system's "central nervous system." This controller enables zero-second switching between pipelines and utilizes AI for failure prediction, ensuring the determinism and reliability of the thermal dissipation chain in a software-defined manner—a hallmark of its systems engineering thinking.

· Infrastructure Convergence ("Cooling-Power Integration"): At the cabinet level, the Liquid Distribution Unit (LDU) and the High-Voltage Power Distribution Unit (PDU) are physically integrated and managed uniformly. This "cooling-power integrated" design is the ultimate engineering response to the ultra-high power density per cabinet, simplifying deployment and improving energy efficiency (lowering PUE). It represents the physical manifestation of its deterministic design philosophy.

b. NVIDIA: The Liquid Cooling Framework of Agile Ecosystem Innovation

This is a design philosophy centered on the GPU, empowering the global ecosystem through the definition of open standards. Its core is to provide a validated "blueprint," lowering the application barrier for the entire industry and enabling efficient, flexible, and large-scale deployment.

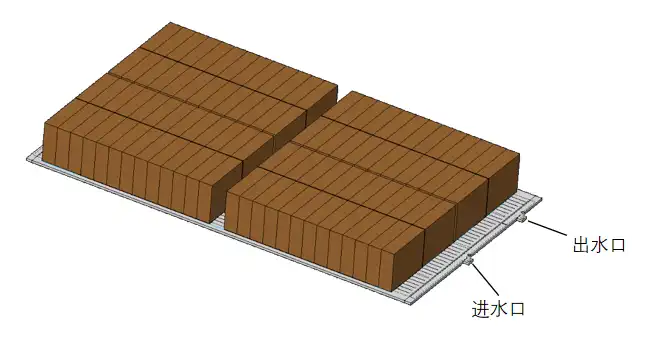

· Chip-level Standardization and Reference Design (VRD): NVIDIA provides detailed thermal reference designs for its GPUs (e.g., the Blackwell series), explicitly defining the performance interfaces for the cold plate, including physical dimensions, Thermal Design Power (TDP), flow rate, and pressure drop. This essentially provides a "standard answer" for all cooling vendors, encapsulating complexity within standardized components and ensuring compatibility and a quality baseline for foundational parts.

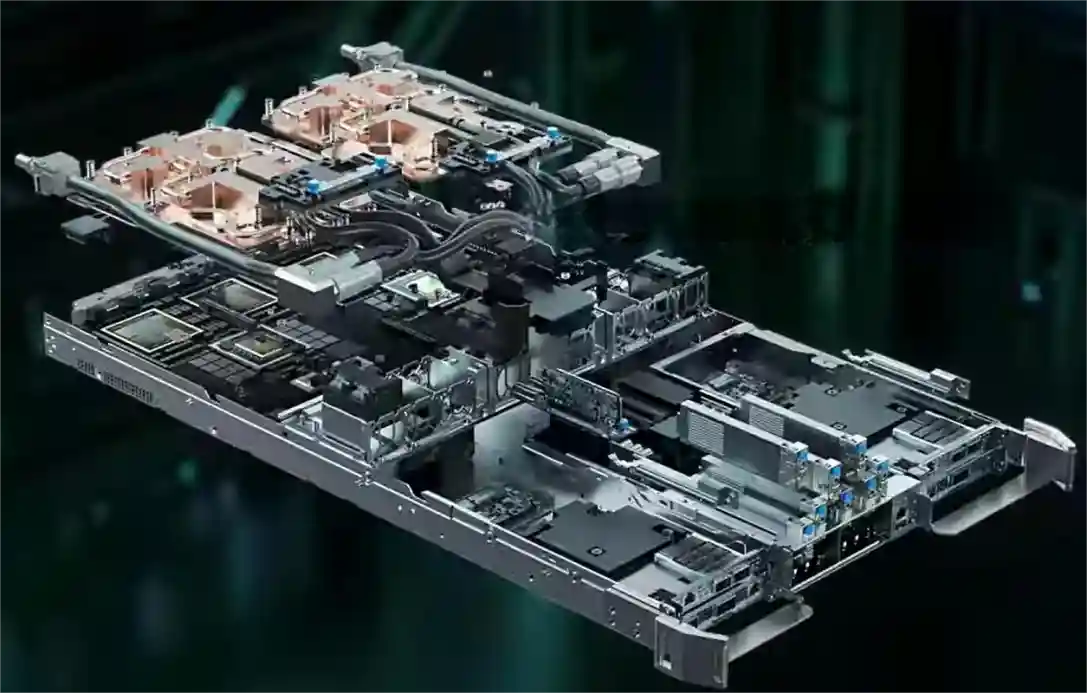

Figure 2: NVIDIA Server Module and Micro-channel Cold Plate

· Ecosystem-level Collaboration and Solution Certification: Engages in deep collaboration with top thermal management and infrastructure vendors like Vertiv and Boyd to jointly develop and certify cabinet-level liquid cooling solutions. For instance, Vertiv's Tier 2 Ready cabinet solution is a pre-validated product developed based on NVIDIA's blueprint, enabling data center operators to rapidly obtain a plug-and-play liquid-cooled cluster as easily as procuring standard equipment.

· Digital Twin Enablement and Deployment Acceleration: Leveraging the NVIDIA Omniverse platform, it provides digital twin and simulation tools for data center liquid cooling systems. Customers can design, verify, and optimize cooling solutions in a virtual environment, significantly reducing the cost and risk of physical validation and achieving agility from design to deployment.

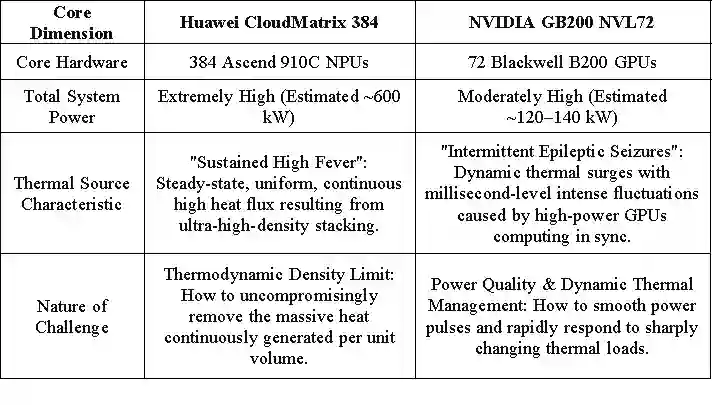

To understand these two paths more clearly, their core differences are compared below:

Table 2: Huawei Model vs. NVIDIA Model: Key Differences at a Glance

3- Historical Inspiration and Future Convergence

The competition between these two paths is not an isolated case in the history of technology. It is, in essence, another classic enactment of systemic integrated innovation versus platform-ecosystem innovation. Huawei resembles Apple during the Steve Jobs era, pursuing absolute control over the product experience from top to bottom. In contrast, NVIDIA is more like today's Google Android, driving the prosperity of an entire ecosystem by setting core standards (the Android system / GPU architecture).

For the industry, the future trend is not about one side completely replacing the other but likely involves a degree of convergence:

· In national or enterprise-level projects pursuing ultimate computing power, the allure of "Deterministic Systems Engineering" remains undiminished.

· In the vast commercial cloud computing market, "Agile Ecosystem Innovation" will continue to expand due to its speed and cost advantages.

· Sparks of ingenuity may emerge at the intersection: incorporating deeper customization and collaborative optimization within open ecological standards.

4- Conclusion

Therefore, the cooling debate between Huawei and NVIDIA is fundamentally a contest between two core competitive strengths in the AI era: one side pursues deterministic, extreme performance through the deep integration of systems engineering; the other drives agile industry innovation and rapid proliferation by building open standards and ecosystems. This duel delineates clear path choices for participants in the industrial chain: to act as a "spearhead force," deeply integrated and tackling specific system-level fortresses, or to serve as the "main force," integrating into the ecosystem to explore markets across the vast plains of standardization. Ultimately, victory lies not only in the technology itself but also in the insight into the logic of industrial evolution and a clear definition of one's position in the future blueprint.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

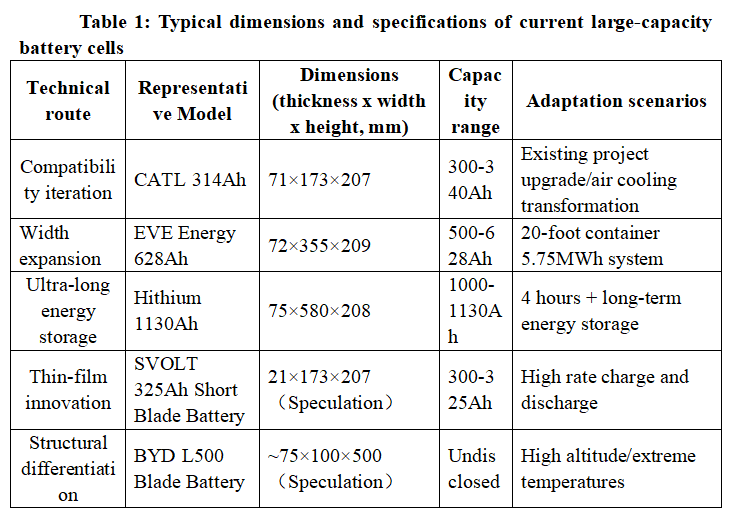

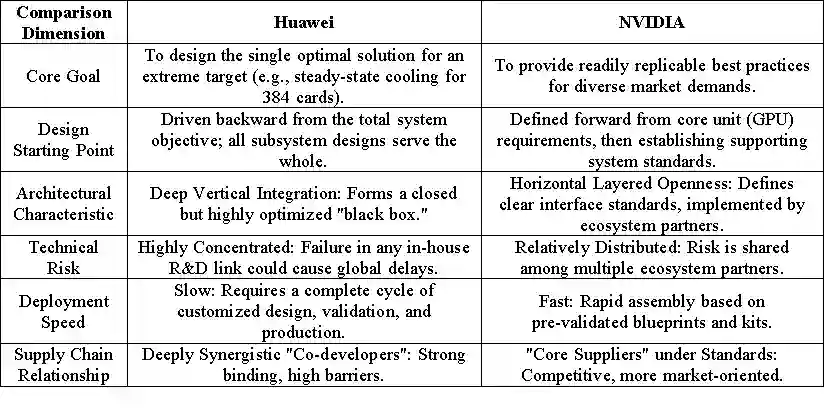

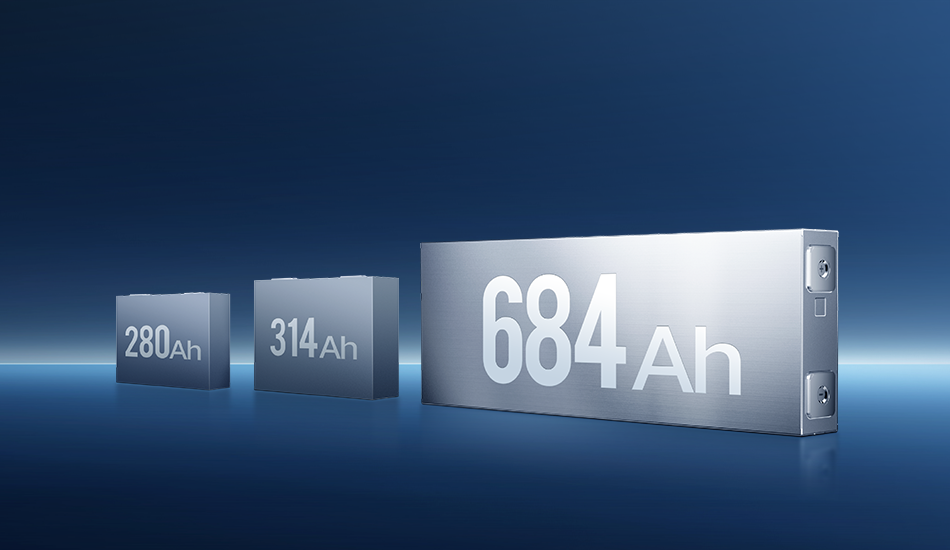

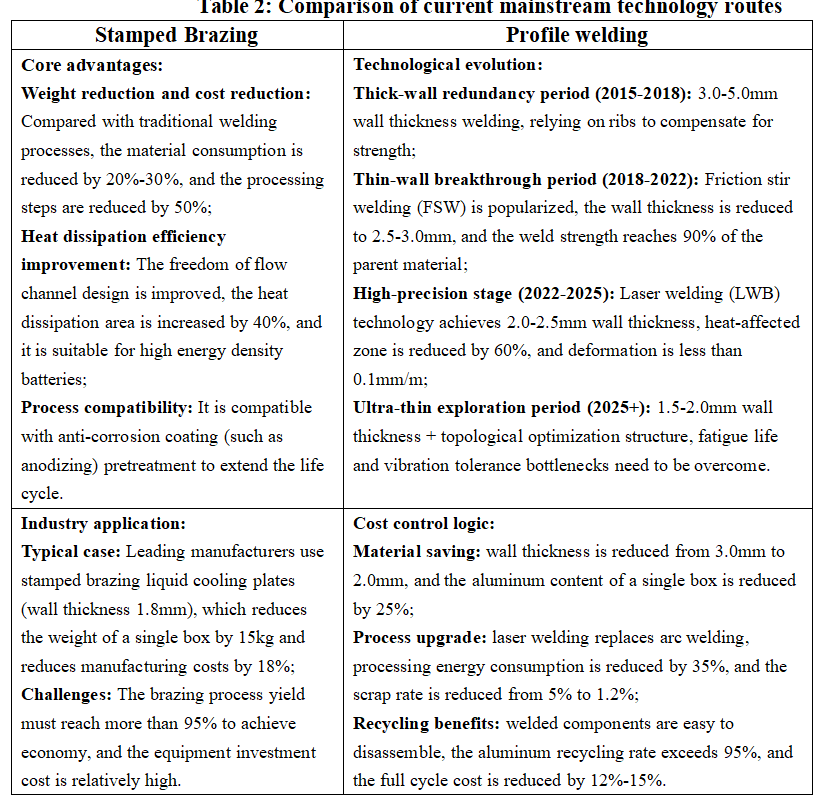

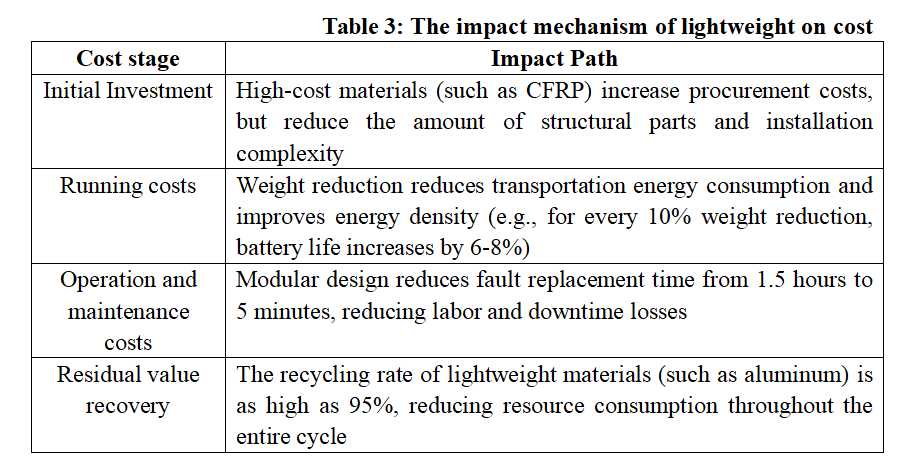

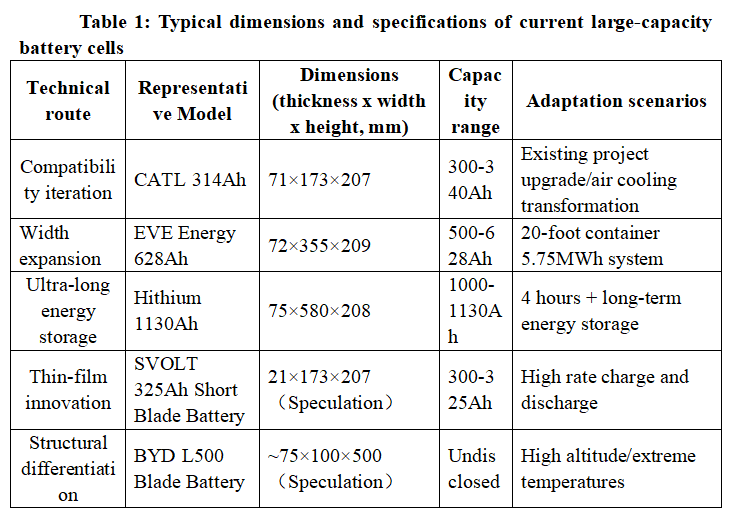

When the "Large" Size of Battery Cells Becomes a Consensus, the "Strength" of the Pack Becomes the New Battleground

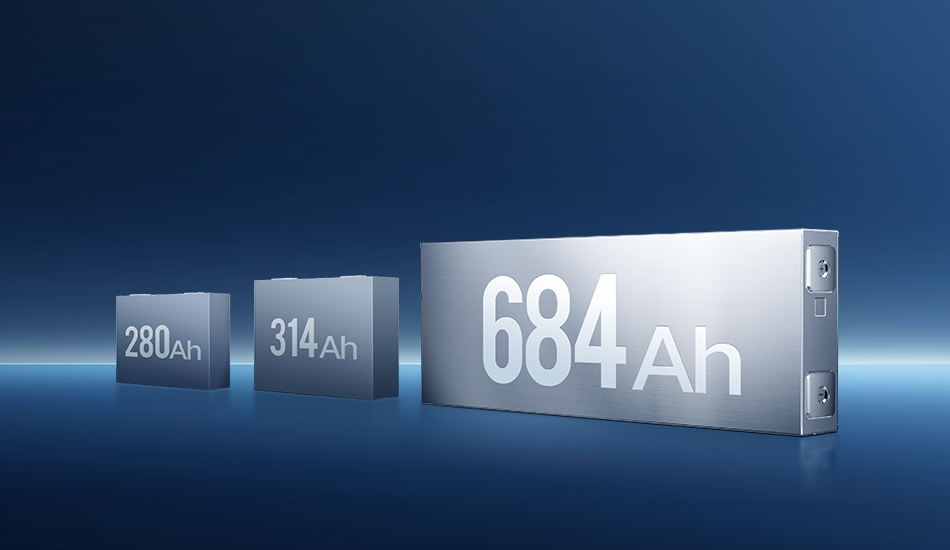

The energy storage industry is entering an era of leapfrogging battery cell capacities, with the shift from 280Ah towards 500Ah+ already underway. While the industry focuses on the "largeness" of cells, the "strength" of the Pack—specifically its mechanical structure's load-bearing and safety mitigation capabilities—is becoming the new competitive focus. Regardless of the evolution in cell chemistry and capacity, the resulting expansion forces, thermal runaway energy, and mechanical loads ultimately must be borne by the Pack's lower enclosure, its mechanical foundation.

From a structural design perspective, this article explores how the Pack lower enclosure can address differentiated mechanical and thermal management demands amidst diverging cell technology pathways, and build sustainably adaptable engineering capabilities.

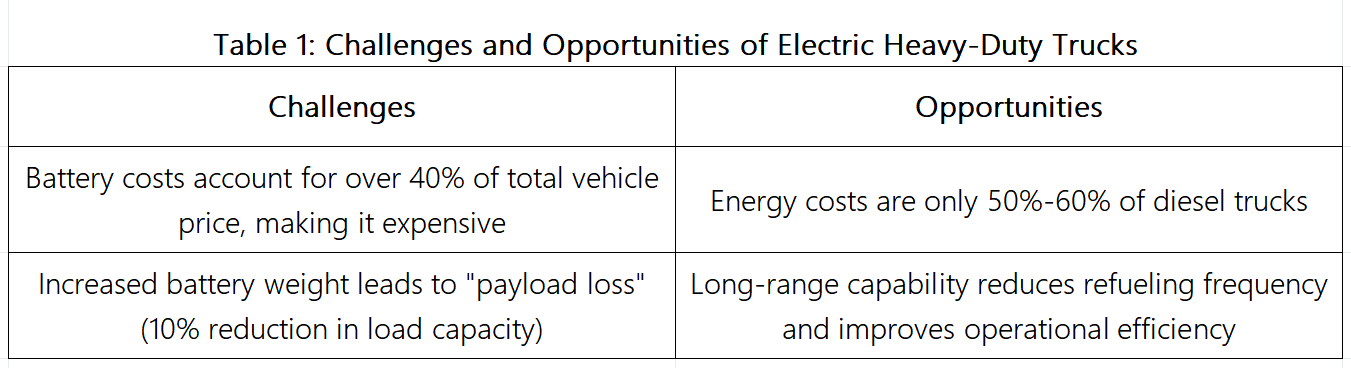

1- Mechanical Analysis of Three Major Technology Paths: The Triangular Challenge of Load, Heat, and Space

The increase in cell capacity directly alters the boundary conditions for Pack system design. As the "skeleton" and "skin" of the system, the lower enclosure must re-address three fundamental questions:

a. Mechanical Analysis for the 587Ah (High-Integration Path)

Core Demand: Achieving energy density ≥6MWh within a standard 20-foot container has spurred ultra-compact layouts like "4 columns, 8 clusters in total."

Lower Enclosure Challenges:

· Structural Load-Bearing Optimization: With increased overall mass but reduced support points, the enclosure must optimize load transfer paths, balancing overall stiffness with local strength in critical areas to ensure structural stability during transportation and operation.

· Integration of Thermal Management Structure: The liquid cooling system is deeply integrated with the enclosure's base plate and support structures, serving both as the thermal management core and participating in overall load-bearing. The design must ensure the long-term reliability of cooling seals under sustained structural loads and thermal cycling.

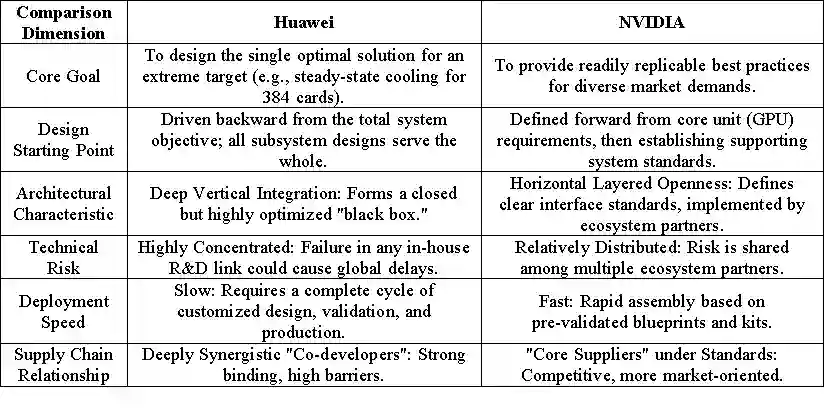

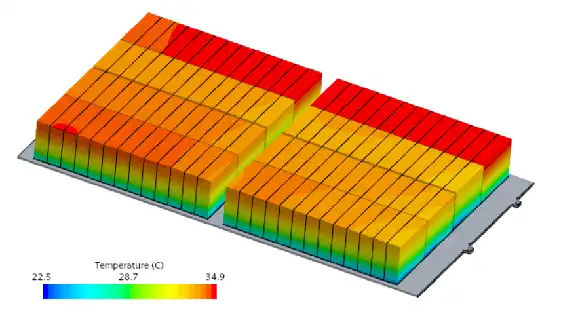

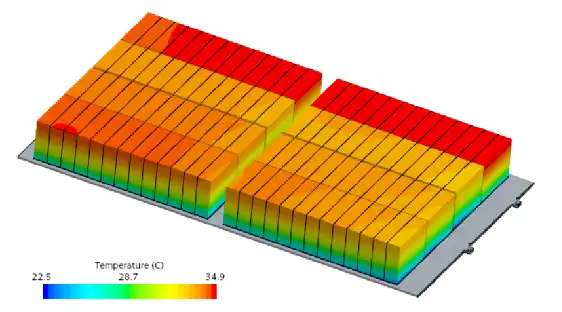

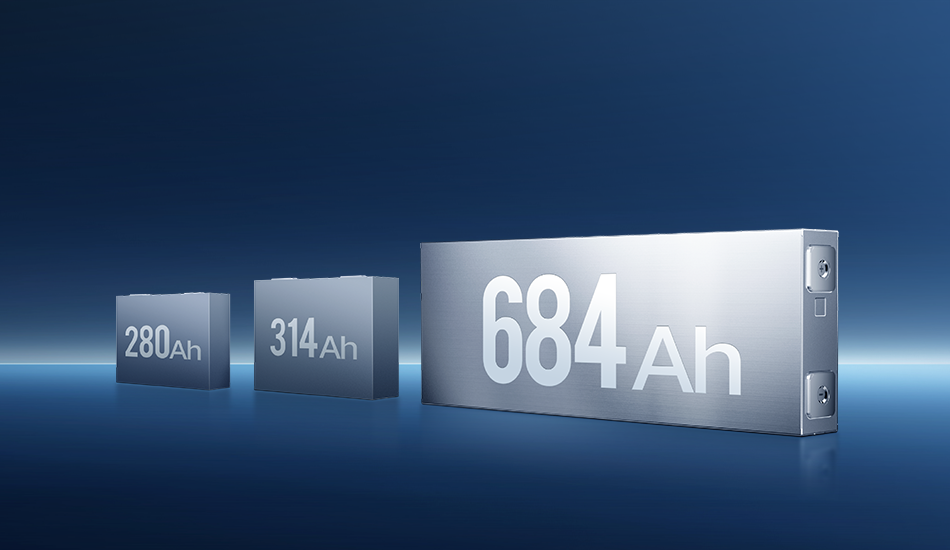

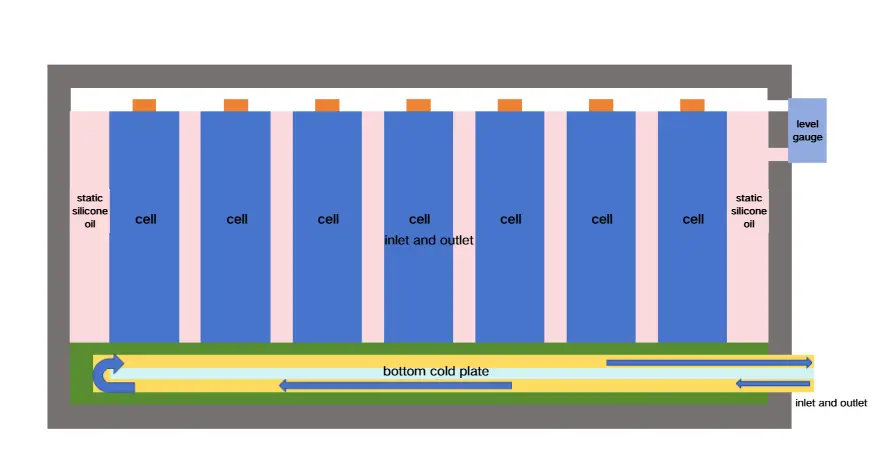

Simulation of Energy Storage Pack Lower Enclosure

· Precise Spatial Coordination: The enclosure must allocate reasonable clearances within the limited space for cell expansion, thermal displacement of electrical connections, fire suppression piping, etc., enabling the reliable coexistence of all subsystems within the compact layout.

b. Thermo-Mechanical and Structural Response Analysis for the 684Ah (Ultra-Large Capacity Path)

Core Demand: Minimizing cost per Wh by maximizing single-cell capacity, which introduces physical centralization effects.

Lower Enclosure Challenges:

· "Focal Point" Effect of Expansion Force: The expansion force of a single cell does not increase linearly with capacity but nearly exponentially. The internal frame of the enclosure requires a more robust and uniform "restraint system" to distribute the concentrated expansion stress across the entire structure, avoiding local plastic deformation.

· "Uniformity" Dilemma in Thermal Management: Larger heat-generating bodies require more efficient heat conduction paths. The material, thickness of the enclosure's base plate, and the design of the contact interface with the cell bottom (such as the compression ratio setting for thermal pads) become critically important. During thermal runaway, the larger energy release places higher demands on the directional venting capability of pressure relief channels and the flame-retardant duration of internal fire barriers.

· Structural Response to Concentrated Weight: Heavier individual cells alter the overall vibration modes of the Pack. The lower enclosure requires renewed fatigue simulation to prevent resonance at specific frequencies leading to fastener loosening or structural cracks.

c. Manufacturing Adaptability Explanation for the 392Ah (Robust Transition Path)

Core Demand: Focuses on balancing performance, cost, and delivery efficiency, providing a thoroughly validated solution to the market.

Lower Enclosure Challenges:

· Stable Realization of Mature Solutions: Ensuring product consistency through strict process control based on a verified design and manufacturing system, supporting rapid and stable mass production schedules.

· Deep Supply Chain Collaboration: Leveraging an established supply system to continuously enhance the product's comprehensive cost competitiveness through material selection, process optimization, and scaled procurement.

2- Engineering Thinking to Address Divergence

Confronted with multiple technology pathways, lower enclosure suppliers cannot rebuild their technical systems for each path. The real solution lies in platform-based, precise response—efficiently adapting to different requirements through scalable, modular design.

a. Focusing on Common Physical Principles and Collaborative Models

Cell iteration follows stable physical laws. We have established a collaborative evaluation process based on core parameters, integrating materials and structural data to rapidly assess the feasibility of new cells. This enables early identification of matching risks, helping to converge design directions and reduce late-stage iterations.

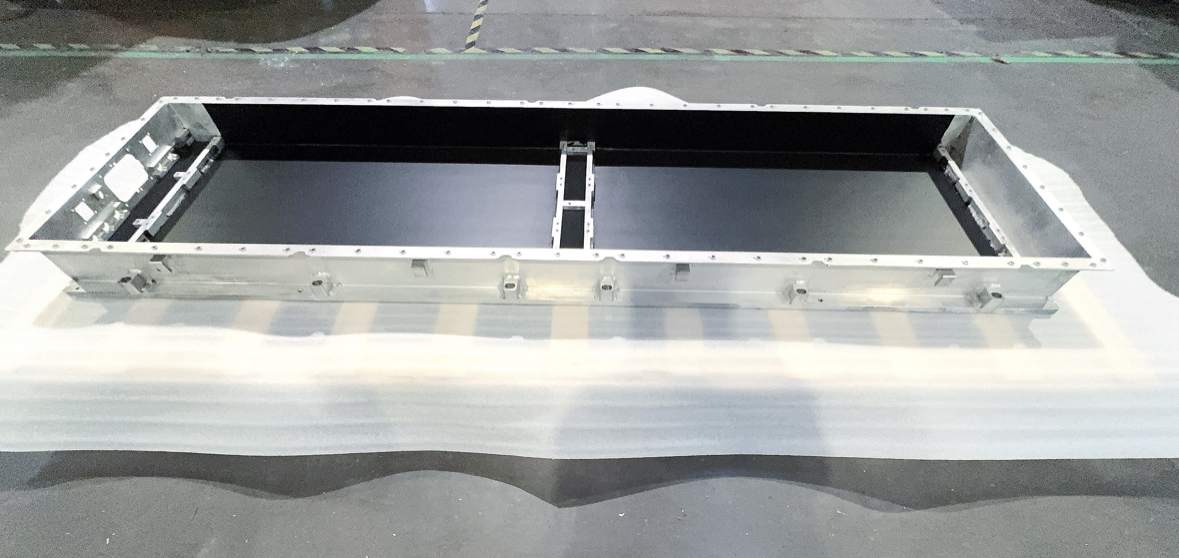

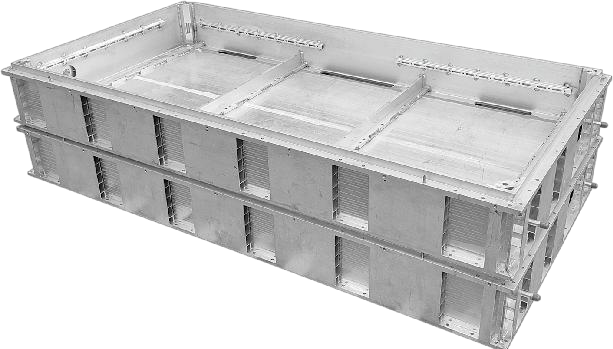

587Ah Energy Storage Battery Pack Lower Chassis

b. Building a Flexible System of "Standardized Interfaces + Configurable Modules"

To address the customization demands arising from technological divergence, we have established a design system with clearly defined interface standardization and internally configurable modules:

· Unified External Interfaces: Installation positioning to the energy storage container, electrical penetration interfaces, cooling system connection points, etc., all strictly adhere to common industry specifications, ensuring compatibility and assembly consistency at the system level.

· Configurable Internal Structure: We offer a series of internal support components and thermal management integration solutions that can be flexibly combined according to cell dimensions and layout.

· Thermal Management Integration Module: The thermal management module adopts a modular design, focusing on optimizing temperature rise control and cell temperature uniformity. It can flexibly adapt to the thermal management needs of different technology paths.

c. Implementing Flexible Production Lines with "Design for Manufacturability"

To match the diversity of technology paths, our manufacturing system is organized around an extensible base platform and modular assembly:

· Base Enclosure Platform Manufacturing: Ensures the precision and consistency of the main structure, providing a reliable carrier for different configurations.

· Modular Assembly Units: Supports flexible selection and assembly of corresponding internal support and thermal management modules based on cell size and layout. Through this setup, we can efficiently switch production for products of different technology paths on the same line, assisting customers in managing supply chain and delivery challenges posed by parallel multi-path development.

3- Redefining the Value of the Lower Enclosure: From Passive Bearing to Active Enablement

The lower enclosure is transitioning from a passive container to a critical system-enabling component, directly impacting safety, energy density, and total lifecycle cost:

a. Safety-Critical Load-Bearing Structure: By providing reliable structural channels and mounting foundations for system-level pressure relief and fire barriers, it works in concert with thermal runaway propagation control to build multi-tiered safety protection.

b. Energy Density Enabler: Lightweight, high-strength design reduces its own weight and spatial footprint, reserving more performance margin for the battery cells and cooling system.

c. Long-Term Reliability Assurance: Structural integrity and fatigue endurance design support the system in withstanding continuous challenges like long-term cycling and transportation vibrations.

4- Conclusion: Building a Bridge Between Diverging Upstream and a Determined Downstream

As battery cell technology evolves, energy storage systems relentlessly pursue safety, high density, and low cost. The lower enclosure must provide a reliable and adaptable foundational support, utilizing modularity and flexible manufacturing to accommodate different technology pathways. Industry competition is shifting towards system-level engineering, where the Pack enclosure serves as a pivotal link.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

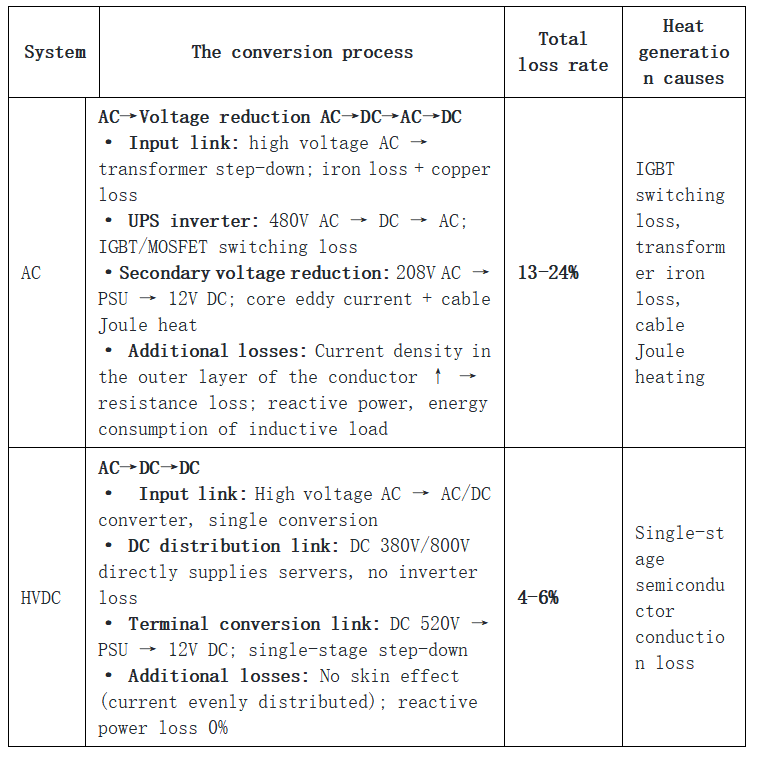

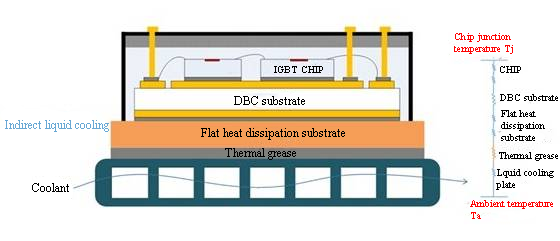

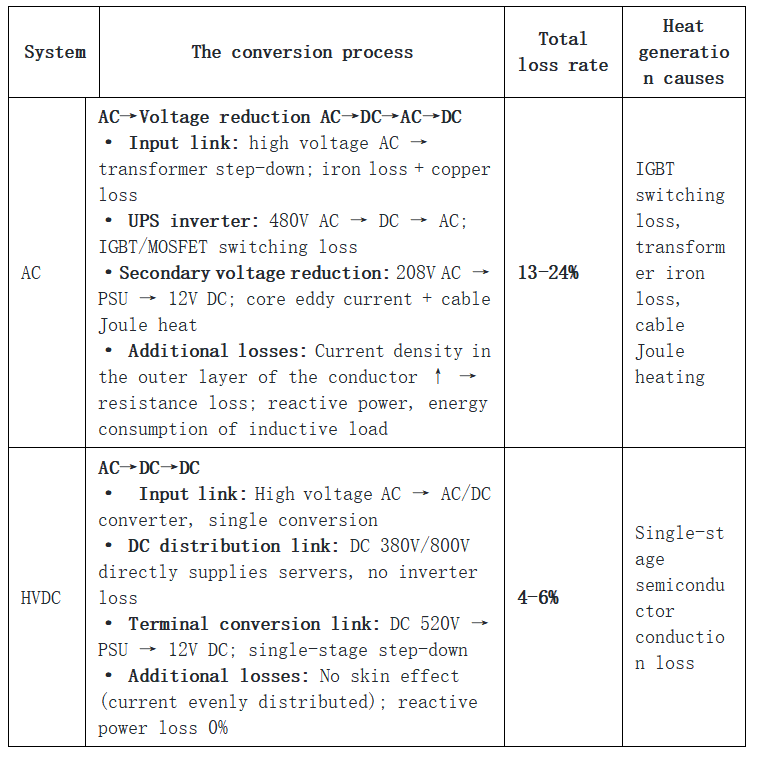

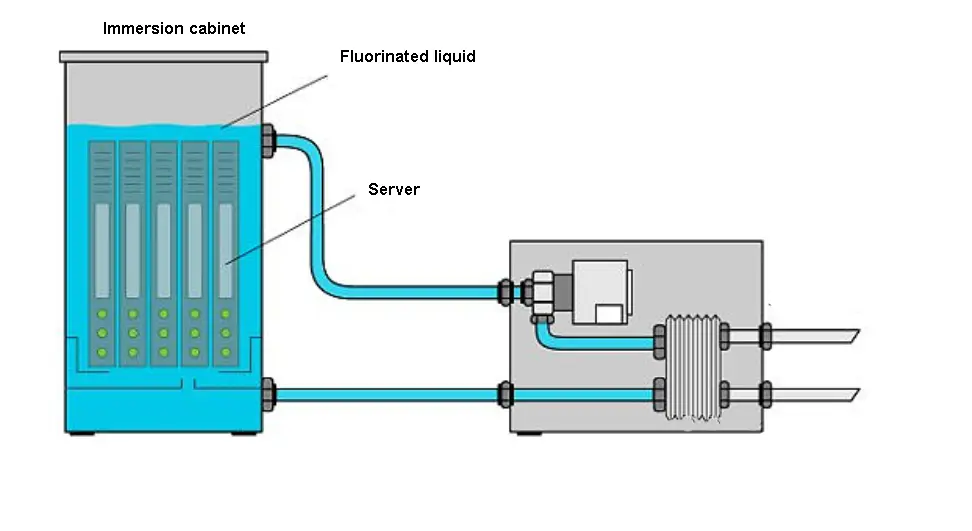

Over the decades of data center development, air cooling technology has consistently been the mainstream choice. However, the launch of NVIDIA's GB200 series products is decisively shattering this equilibrium. As computational density reaches new heights, traditional cooling methods can no longer meet the demands. Liquid cooling technology is now formally stepping from behind the scenes to center stage, becoming the critical infrastructure supporting AI computing power.

1- Fundamental Shifts on the Demand Side

a. Power Density Breaks the Critical Point

The power density of a GB200 NVL72 rack is projected to exceed 30 kW per rack, a figure far beyond the 15-20 kW thermal dissipation limit of traditional air cooling. This signifies:

· An Inevitable Choice of Technology Path: Liquid cooling transitions from "worth considering" to the "only viable option."

· A Qualitative Change in Market Scope: Each GB200 deployment represents a definitive demand for liquid cooling.

· A Significant Increase in Value: The liquid cooling system for a single rack reaches a value level of several hundred thousand RMB.

b. Reliability Requirements Are Upgraded

As the compute density per rack increases, the business value it carries grows exponentially. The reliability of the liquid cooling system is directly linked to:

· Business Continuity: A single cooling failure could lead to computing power losses worth millions.

· System Lifespan: For every 10°C temperature increase, the lifespan of electronic components is halved.

· Performance Stability: Cooling efficiency directly impacts whether chips can sustain peak performance.

2- Comprehensive Enhancement of Technical Requirements

a. Leap in Cooling Efficiency Demands

The GB200 places unprecedented demands on the cooling system:

· Doubling of Heat Transfer Performance: The thermal conductivity of cooling plates needs to be 3-5 times that of traditional solutions.

· Order-of-Magnitude Reduction in Contact Thermal Resistance: Requires contact thermal resistance to be reduced by one order of magnitude.

Figure 1 - Microchannel cold plate

b. Flow Rate Precision Control

· Requires flow control accuracy within ±1%.

· Supports dynamic flow rate adjustment to adapt to different load conditions.

c. Temperature Uniformity

· Temperature difference across the chip surface must be controlled within 5°C.

· Prevents local hotspots from affecting system stability.

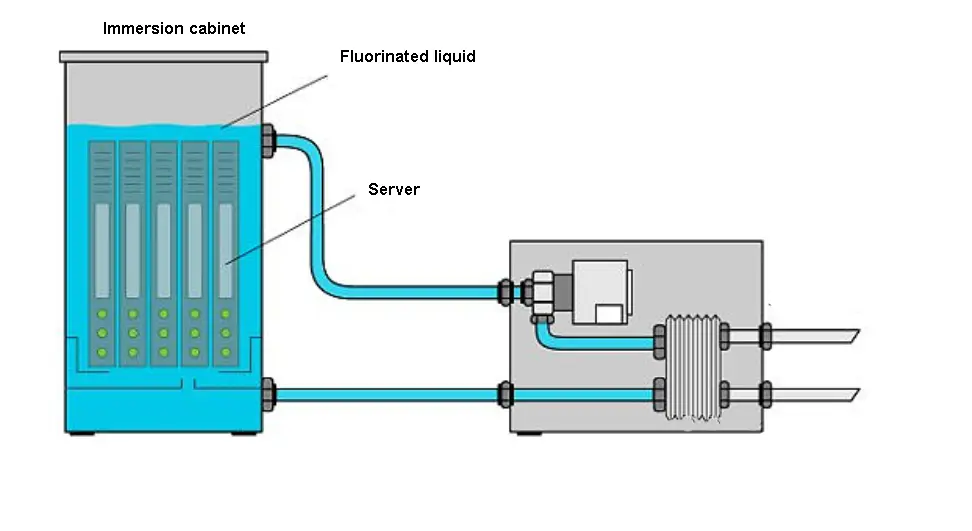

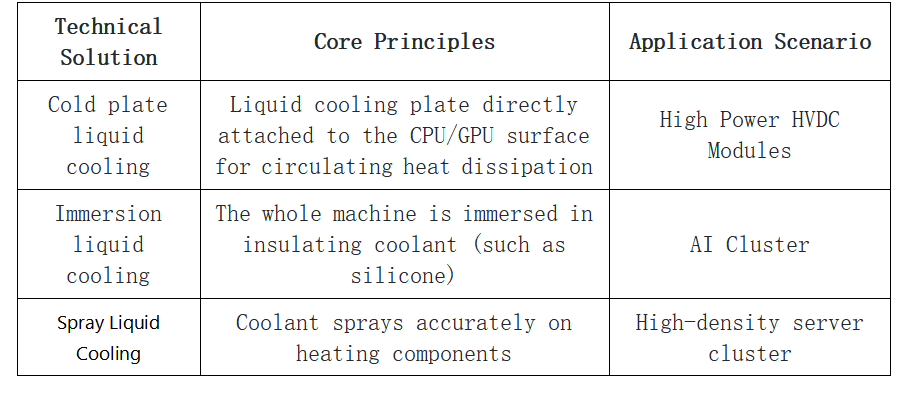

3- Leap in System Integration Complexity

Liquid cooling systems have evolved from simple component supply to complex system engineering:

a. Traditional Model:

· Provision of standardized cooling plates.

· Simple piping connections.

· Basic monitoring functionality.

b. The GB200 Era:

· Rack-level liquid cooling architecture design.

· Intelligent flow distribution systems.

· Real-time health status monitoring.

· Predictive maintenance capabilities.

Figure 2 - NVIDIA GB200 cabinet

4- Comprehensive Elevation of Competitive Barriers

In the new market environment, companies must now clear significantly higher thresholds:

a. Technical Barriers

Liquid cooling companies must break through the limitations of single disciplines and build a comprehensive, cross-disciplinary technological system. The deep integration of multi-disciplinary technologies such as microchannel design, materials science, and fluid dynamics has become the basic entry requirement. Furthermore, capabilities in chip-level thermal simulation and optimization truly test a company's profound technical accumulation. This is no longer merely a matter of simple process improvement, but a systemic engineering challenge requiring long-term R&D investment.

b. Certification Barriers

The industry certification system is becoming increasingly stringent. Companies must not only pass the rigorous reliability tests mandated by server manufacturers but also obtain technical certification from the original chip manufacturers. This dual certification requirement not only validates a product's technical performance but also rigorously tests a company's quality management systems and its ability to ensure stable, continuous supply. It has become an essential passport for entering the core supply chain.

c. Service Barriers

As liquid cooling systems are upgraded to core subsystems, service capability has become a critical competitive factor. Companies must establish nationwide rapid-response networks and build professional, 24/7 operational and maintenance systems. This service capability demands not just the timeliness of technical support but also comprehensive end-to-end service solutions encompassing preventative maintenance and emergency response, truly positioning the company as a trustworthy partner for its clients.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

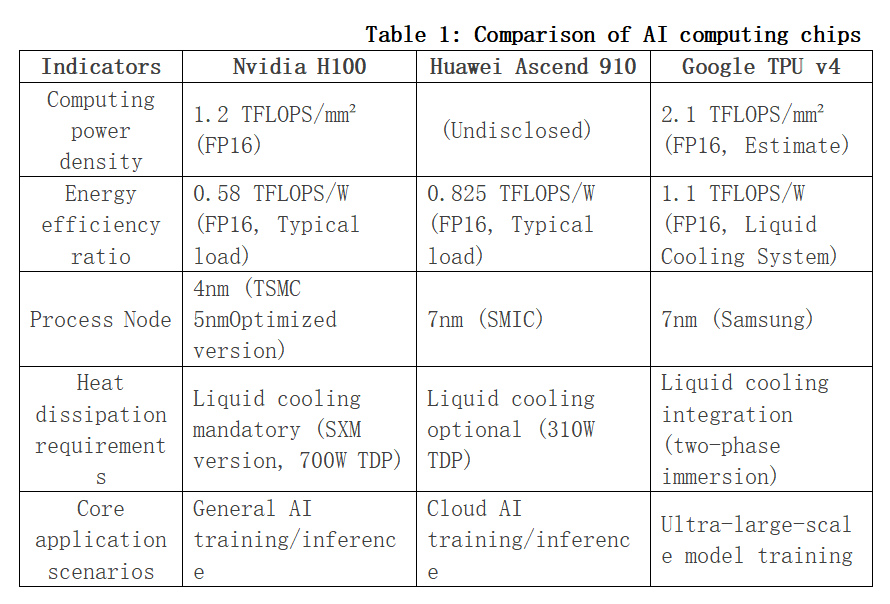

In the history of computing architecture evolution, certain moments do not arrive silently. The launch of NVIDIA's GB200 NVL72 is one such moment—it is not merely a new product, but a complete reconceptualization of the server itself.

For three decades, a "server" has consistently meant a standardized chassis unit: containing a motherboard, CPU, memory, storage drives, and expansion cards, interconnected via industry-standard interfaces. We measure it in "U"s, rack and stack it in cabinets, and connect to it over networks. However, the emergence of the GB200 NVL72 is fundamentally dissolving this long-standing definition at its core.

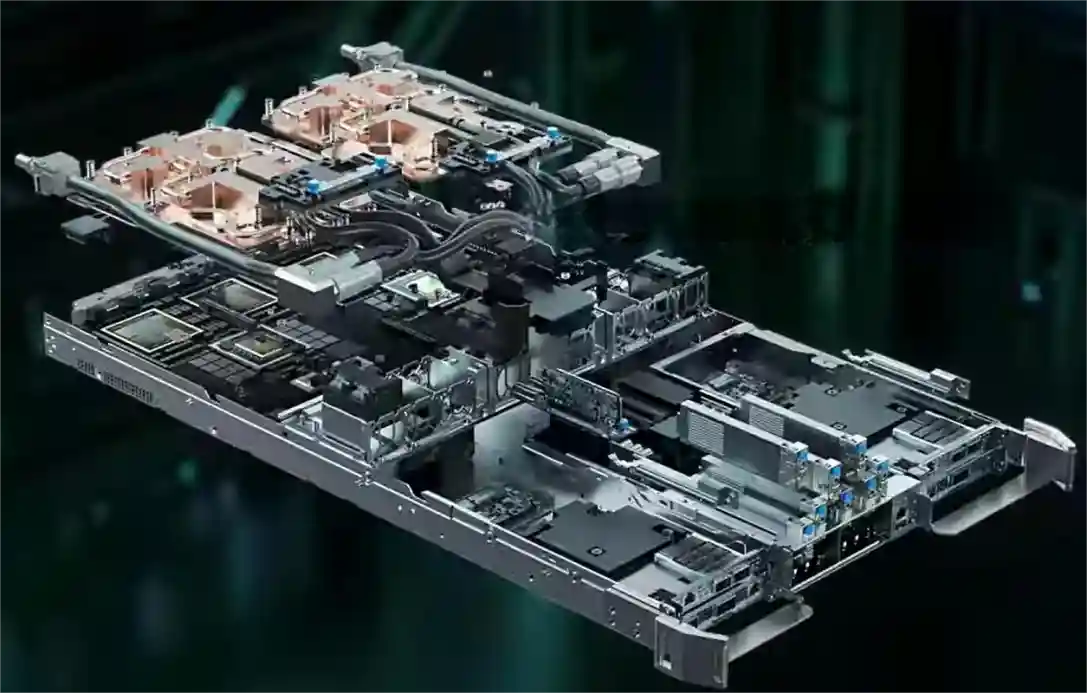

Its essence is no longer "a server," but rather a "computer" that takes the form of an entire rack. Traditional server components are deconstructed and then reintegrated on a grander scale—via NVLink-C2C, liquid cooling, and rack-scale power management—into an indivisible computational whole. This is no simple upgrade; it is a profound paradigm shift.

1- What is a "Server"? The Answer to This Question is Changing

For three decades, our understanding of a server has been a standardized chassis: inside resides a motherboard, CPU, memory, storage drives, and expansion cards, all adhering to industry standards, allowing for arbitrary replacement and upgrade.

But the change brought by the GB200 is fundamental:

· The computational heart is no longer discrete CPUs and GPUs, but the GB200 Superchip—a holistic entity deeply integrating a CPU and a GPU.

· Interconnect no longer relies on standard PCIe slots, but on customized NVLink backplanes.

· Cooling is no longer an optional accessory, but an integrated liquid cooling system.

· The fundamental unit of deployment has shifted from the "chassis" to the "rack."

The various components of the traditional server have been "torn apart," only to be reassembled and integrated anew at the larger scale of the rack. This is not evolution; it is re-architecture.

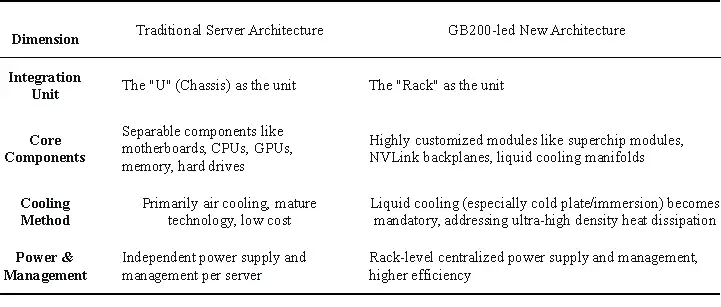

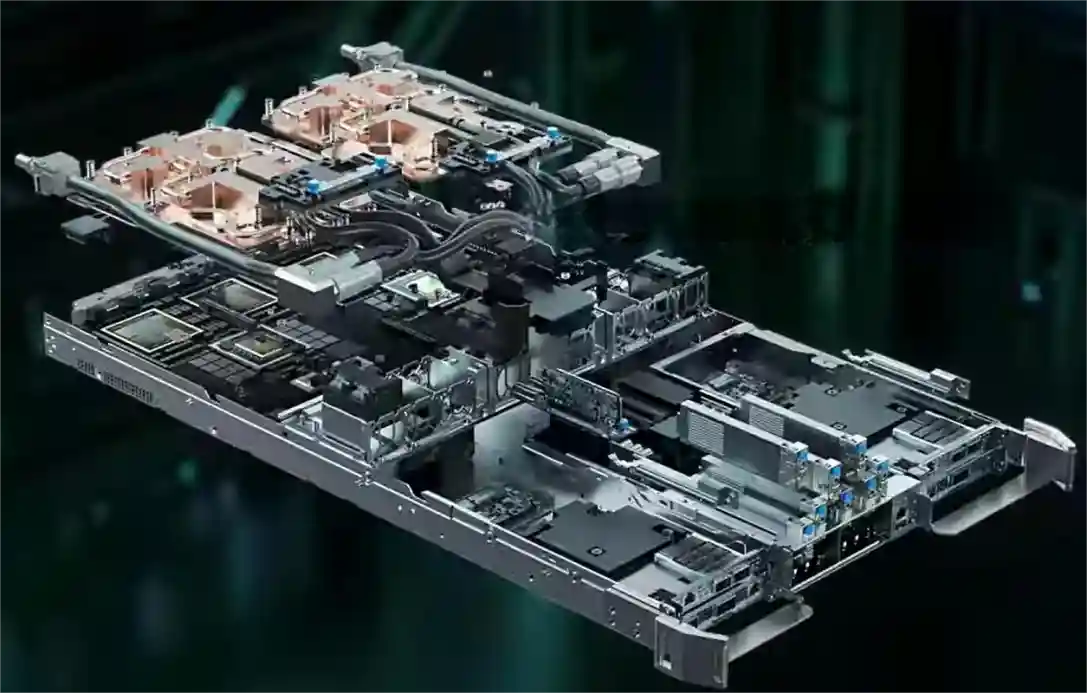

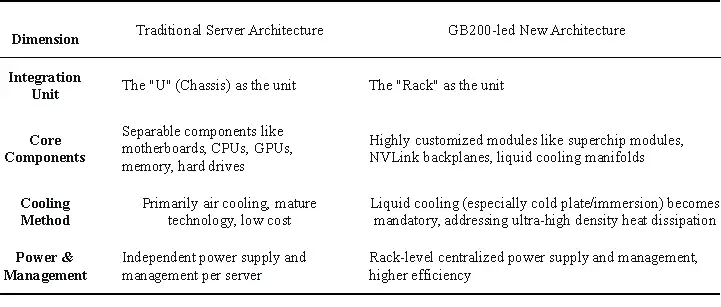

Table 1 - Reshaping the Physical Architecture: From "Chassis" to "Rack"

2- The Three Pillars of "Rack-Scale Architecture"

Traditional server design involves balancing trade-offs within a sealed chassis. In contrast, the rack-scale architecture represented by the GB200 approaches cooling, interconnect, power, and management as a complete system, designed holistically at a top level in a new dimension. This is no longer about stacking components, but about deep, system-level integration. This relies on the synergistic innovation of three core pillars working together.

Pillar One: From "Network Interconnect" to "Backplane Bus"

In traditional data centers, servers are independent nodes communicating over a network (like Ethernet). Within the GB200 NVL72, however, the NVLink Fabric functionally replaces the traditional motherboard bus, becoming the "skeleton" connecting all computing units. This shift enables the 72 GPUs in the rack to work in concert like a single, massive GPU, achieving orders-of-magnitude improvements in communication bandwidth and latency.

Pillar Two: Cooling Evolves from "Supporting Facility" to "Core Subsystem"

When computational density progresses from tens of kilowatts per rack to hundreds of kilowatts, traditional air cooling becomes ineffective. Liquid cooling is no longer an optional "supporting facility"; it has become a core subsystem on par with computing and interconnect. Its design directly determines the overall system's performance output and operational stability, making it the key factor in transitioning from "usable" to "high-performance."

Pillar Three: The "Centralization and Re-architecting" of Management and Power

The GB200 adopts rack-level centralized power supply and management. This is not merely about pursuing higher power conversion efficiency, but also a redefinition of system coupling. It brings benefits like simplified cabling and unified management visibility. However, it also expands the potential failure domain from a single server to the entire rack, placing new paradigm-level demands on operational maintenance.

3- The Restructuring and Shift of the Value Chain

The influence of the "rack-scale architecture" represented by the GB200 extends far beyond technology itself, clearly outlining a new industry value chain curve. Traditional value distribution is being disrupted, while new high-value strongholds are quietly forming around system-level integration and hardware-software co-design.

Server Vendors: Strategic Transformation from 'Definers' to 'Integrators'

Traditional server giants, like Dell and HPE, are facing a migration of their core value. The capabilities they once thrived on—motherboard design, system optimization, and standardized manufacturing—are seeing their importance diminish within highly customized, pre-integrated systems like the GB200.

However, new strategic opportunities lie within this crisis:

· Value Moving Upstream: The competitive focus shifts from internal server design to rack-level liquid cooling, power efficiency, and structural layout.

· Value Extending Outward: Core competitiveness extends from hardware manufacturing to professional services for large-scale deployment, cross-platform operational management, and integration capabilities with enterprise IT environments.

This signifies that the role of server vendors is transforming from being "definers" of standard products to becoming "advanced integrators and enablers" of complex systems.

Cloud Vendors' 'Strategic Procurement': Balancing Dependency and Autonomy

For hyperscale cloud vendors, the GB200 is both a strategic necessity and a strategic warning.

· Short-term Tactic: As the ultimate benchmark for computing power, procuring GB200 is an inevitable choice to meet market demand for top-tier AI compute.

· Long-term Strategy: To mitigate supply chain risks and technology lock-in, developing in-house AI chips (like TPU, Trainium, Inferentia) has become a core strategy crucial for future autonomy.

The actions of cloud vendors vividly reflect the complex trade-offs between efficiency and autonomy, and between short-term market needs and long-term control.

The Evolution of End-User Decision-Making: From Evaluating 'Components' to Assessing 'Output'

For end-user technical decision-makers (CTOs, Technical VPs), the procurement evaluation paradigm is undergoing a fundamental shift.

Traditional Procurement Checklist:

· CPU core count and clock speed

· GPU model and quantity

· Memory and storage capacity and speed

Current Strategic Considerations:

· Efficiency Metrics: Performance per watt, total model training time

· Total Cost of Ownership (TCO): Comprehensive cost including hardware, energy consumption, maintenance, and manpower

· Business Agility: Time cycle from deployment to productive output

This shift marks a critical evolution in corporate technology procurement from a cost-center mindset to a productivity-investment mindset.

The GB200 has redefined the compute unit—from the "server" to the "rack." This is not merely a performance upgrade, but a complete paradigm shift in architecture. The pursuit of efficiency has transcended mere component stacking, and the industry value chain is being restructured. In this transformation, the only certainty is this: adapt to it, or be left behind.

A new computational epoch has begun.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

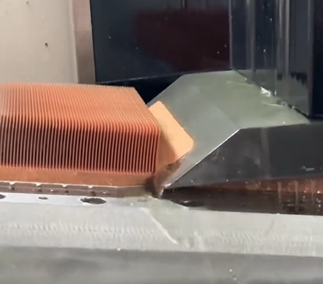

When your device has multiple core hot spots that are independent of each other, have varying power consumption, or require isolated cooling, traditional single-channel cold plates become inadequate. Multi-loop copper tube embedded cold plates are the key to overcoming this challenge.

1-Why Choose Multi-Loop? Three Scenarios That Address Key Pain Points

a.Isolate Thermal Interference to Ensure Core Unit Performance

When components such as IGBTs and diodes, or CPUs and GPUs, are densely arranged, a single flow channel can cause thermal "crosstalk," forcing low-temperature components to operate in high-temperature environments. The multi-loop design acts like a "dedicated air conditioner" for each component, completely eliminating thermal interference and ensuring each unit operates within its optimal temperature range, thereby enhancing overall system performance and stability.

b. Achieve System Redundancy for High-Reliability Architecture

In fields with extremely high reliability requirements, such as servers and communication base stations, the failure of a single cooling loop can lead to system downtime. The multi-loop design enables the construction of an "N+1" redundant cooling system. If one loop fails unexpectedly, the remaining loops can still provide basic cooling capacity, buying valuable time for system maintenance. This serves as the cornerstone of high-availability design.

c. Address Irregular Layouts and Differentiated Cooling Needs

For irregularly arranged heat sources, a single flow channel struggles to achieve uniform cooling. The multi-loop solution supports "tailored designs," allowing you to customize the path of each copper tube flexibly based on the actual shape and layout of the heat sources. This ensures optimal flow paths precisely covering every hot spot. Additionally, high-power consumption components can be assigned high-flow loops, while low-power consumption components can be assigned low-flow loops, achieving the optimal allocation of cooling resources.

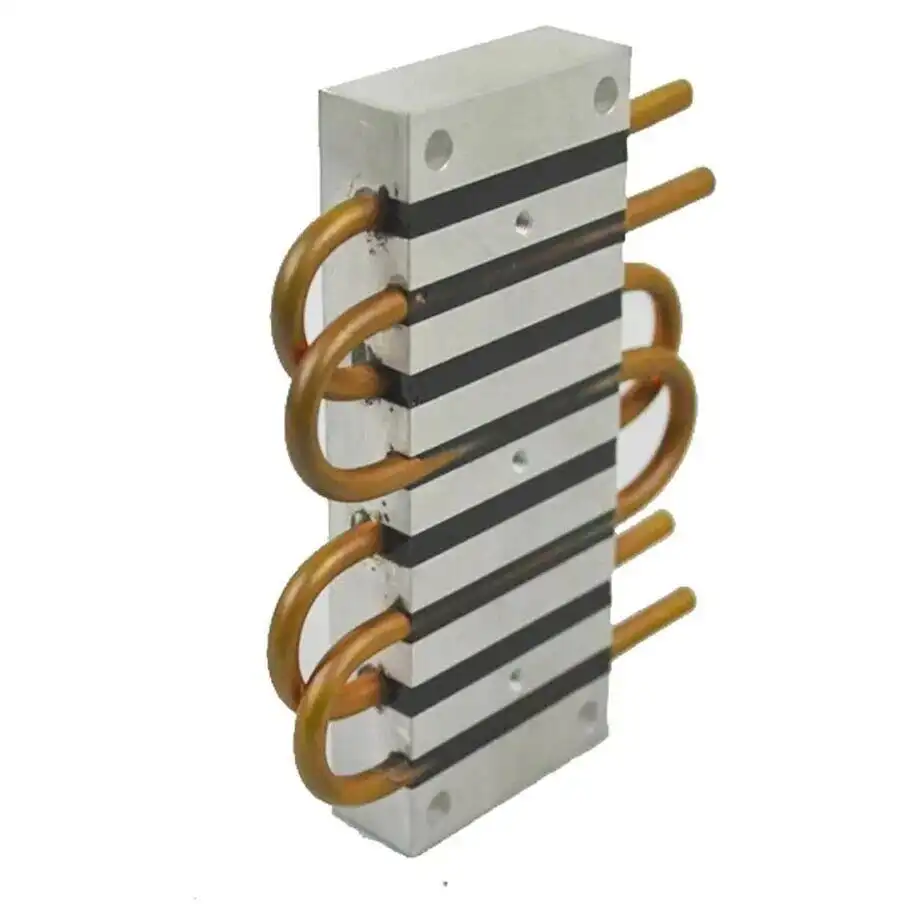

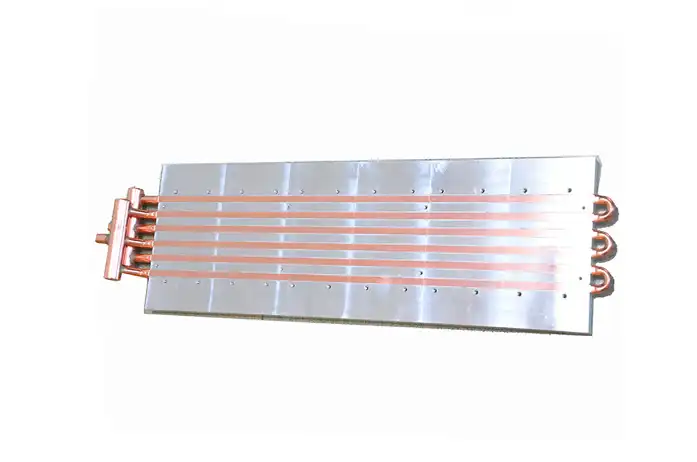

Figure 1: Multi-loop embedded copper tube cold plate

2-The Core of Design and Manufacturing: How to Balance Performance and Reliability in a Compact Space?

In multi-loop designs, the spacing between flow channels is critical to success.

a. Thermal Bottom Line: Preventing "Thermal Short Circuits"

If the spacing between adjacent flow channels is too narrow, even with independent channels, heat can rapidly conduct through the aluminum substrate in between, significantly compromising the isolation effect. Through simulation and testing, we have established a fundamental spacing principle of ≥1.5 times the tube diameter to ensure thermal independence.

b. Structural Red Line: Upholding the "Pressure-Bearing Lifeline"

The aluminum substrate between flow channels is a weak point for withstanding internal pressure. Excessively narrow spacing can lead to insufficient rib strength, posing a risk of tearing under pressure impact. Through mechanical stress simulation, we ensure that the stress between flow channels remains well below the material's yield limit under all operating conditions, fundamentally eliminating the risk of "plate rupture."

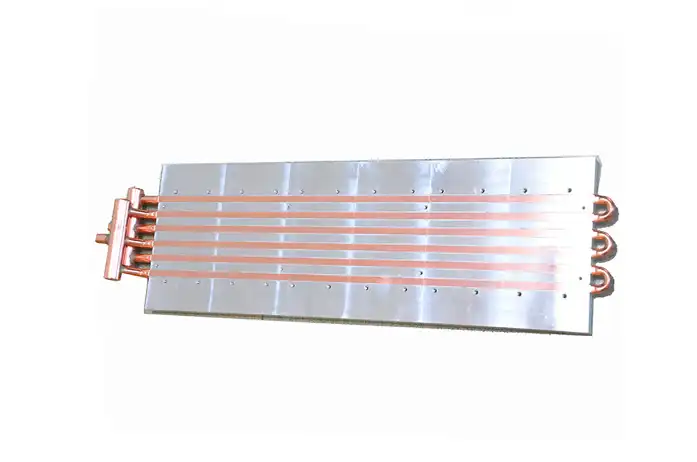

Figure 2: Embedded copper tube cold plate

c. Process Limits: Ensuring "Precision Manufacturing"

Narrow spacing poses a significant challenge for milling cutters. Based on extensive manufacturing experience, we correlate spacing with cutter diameter to ensure efficient machining while achieving smooth and flat channel walls. This lays the foundation for the subsequent tight nesting of copper tubes and low thermal resistance bonding.

3- Key Engineering Implementation Considerations

A successful multi-loop design requires attention to the following key aspects:

a. Collaborative Design

It is recommended to integrate thermal and mechanical design from the conceptual stage, taking into account flow channel layout, structural strength, and process capabilities to avoid subsequent design changes.

b. Process Control

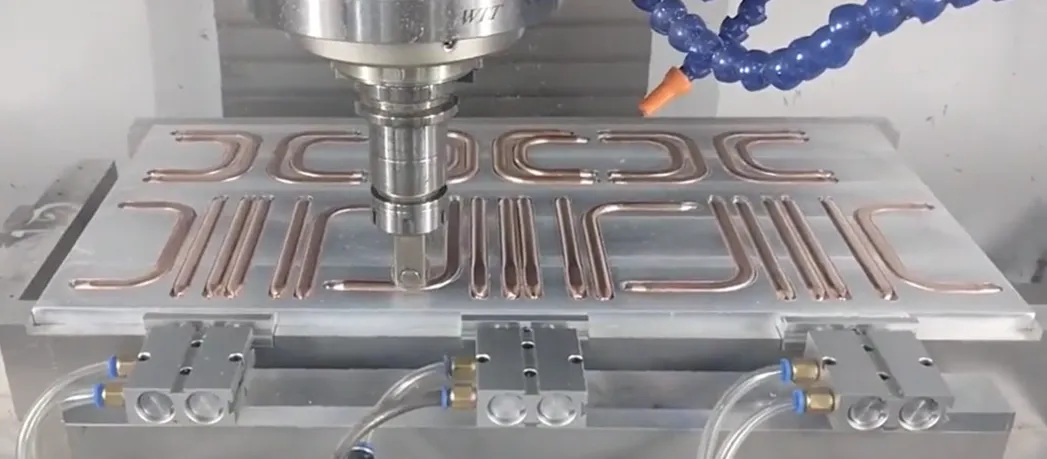

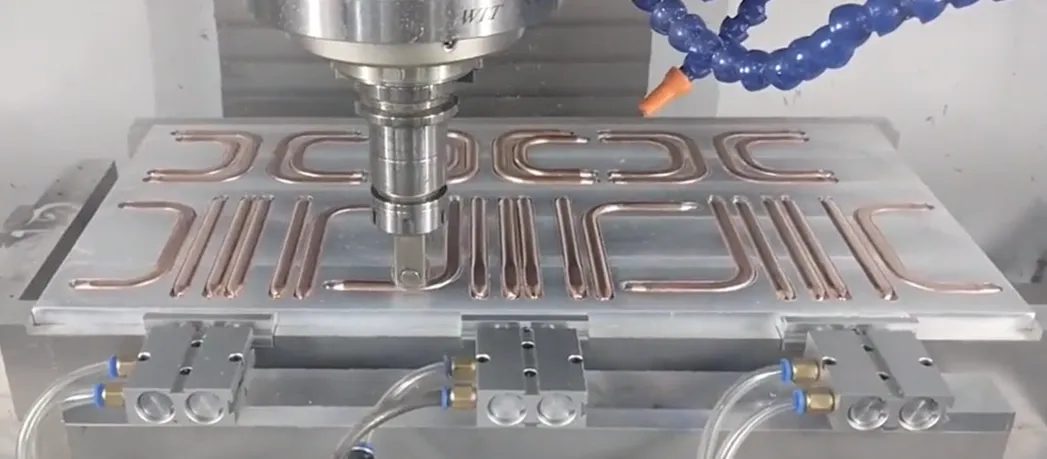

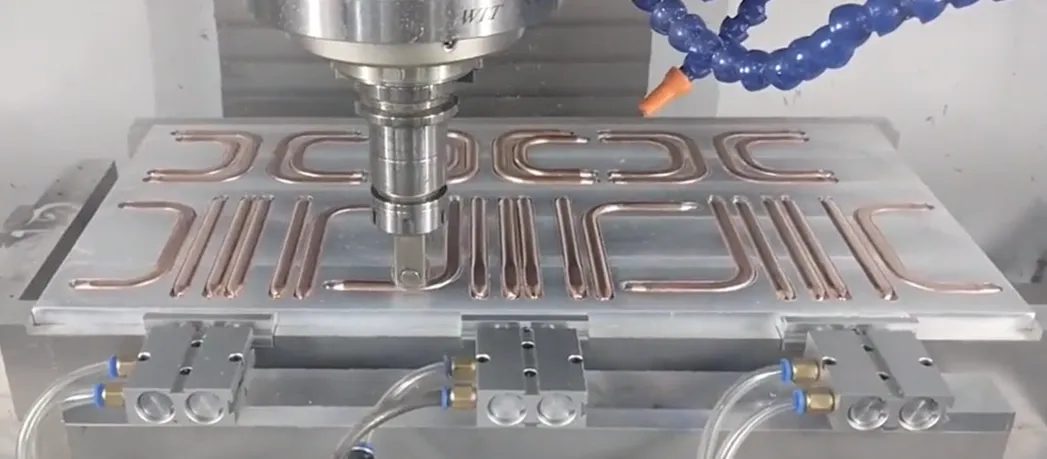

• Utilize high-precision CNC milling for channels to ensure slot width tolerance and surface quality.

• Employ mandrel bending technology for copper tubes to maintain post-bending通畅性 and uniform wall thickness.

• Implement reliable nesting and fixation processes to prevent copper tube displacement under vibration conditions.

c. Verification Testing

A comprehensive testing system includes:

• 100% air tightness testing

• Flow rate–pressure drop characteristic testing

• Thermal resistance performance verification

• Burst pressure testing

In summary, multi-loop copper tube embedded cold plates are a powerful solution for addressing complex multi-heat source cooling challenges. The key to success lies in a deep understanding of their design logic and finding the optimal balance between performance and reliability.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

1-Copper Tube Pre-treatment (Bending and Flattening)

Objective: To shape straight round copper tubes into flattened forms that exactly match the designed flow paths.

a. Material Selection: Why Oxygen-Free Copper?

Oxygen-free copper (C1220) has a purity of up to 99.9% and is free of grain boundary oxides, giving it excellent ductility, making it as malleable as dough. It is less prone to cracking or micro-cracking during bending and flattening, ensuring subsequent reliability.

b. Bending Radius: The Safety Bottom Line

The minimum bending radius must be ≥ 1.5 times the tube diameter—this is an iron rule. If this value is exceeded, the outer wall of the copper tube will be over-stretched, leading to thinning or even rupture. Using a mandrel bending machine is key to preventing wrinkling on the inner side.

c. Flattening: A Precise "Slimming" Process

Flattening is not simply about crushing the tube; it involves controlled plastic deformation through precision molds. The height of the flow channel after flattening must not be less than 30% of the original inner diameter. The core goal is to ensure uniform wall thickness after flattening, avoiding local dead folds or excessive thinning, as such defects would become potential leakage points in the future.

Figure 1: Heat Pipe Bending

d. Process Decision: Bend First or Flatten First?

It must be "bend first, then flatten." Bending round tubes is a mature and controllable process. If flattened first, the flattened tube can hardly undergo small-radius, high-quality bending, and the inner wall of the flow channel would be severely deformed, causing a sharp increase in flow resistance.

2-Substrate Processing (Precision Groove Milling)

Objective: To machine precisely dimensioned "tracks" on the aluminum substrate for embedding the copper tubes.

Figure 2: Embedded Copper Tube

a. Groove Width Design: Interference Fit

The groove width must be designed slightly smaller than the width of the flattened copper tube (typically by 0.05-0.1 mm) to form an "interference fit." This utilizes frictional force to tightly "grip" the copper tube, which is the foundation for initial fixation and reducing contact thermal resistance.

b. Groove Depth Control: Skiving Allowance

The groove depth determines the height by which the copper tube protrudes above the substrate surface after embedding. This height constitutes the machining allowance for the subsequent skiving process. The consistency of the groove depth directly affects the uniformity of the final remaining wall thickness of the copper tube.

c. Tooling and "Tool Chatter"

When milling narrow and deep grooves, an excessively large length-to-diameter ratio of the milling cutter can easily cause "chatter." This leads to rough groove walls and dimensional inaccuracies. Therefore, the flow channel spacing cannot be too small; sufficient space must be reserved for tool strength and rigidity.

d. Cleanliness: The Invisible Quality Factor

After groove milling, aluminum chips and oil stains must be 100% removed. Any residue will form a thermal barrier between the copper tube and the aluminum substrate, significantly increasing the contact thermal resistance and causing a substantial degradation in thermal performance.

3-Nesting and Fixation

Objective: To precisely embed the formed copper tube into the substrate groove and form a stable bond.

a. Interference Fit: The Primary Fixation Force

Relying on precise dimensional design, an external force from a press is used to "squeeze" the copper tube into the slightly narrower groove. The elastic restoring force of the material itself generates a significant normal pressure, which is the primary source of the fixation force.

Figure 3: Heat Pipe Securing

b. Auxiliary Fixation: Preventing the "Seesaw Effect"

Relying solely on the interference fit, the ends of the copper tube may lift under thermal stress. Auxiliary fixation is required: micro-spot welding (high strength, requires thermal control) or high thermal conductivity epoxy resin (low stress, but has aging risks).

c. The Enemy of Interface Thermal Resistance

Air between the copper tube and the aluminum groove is a poor conductor of heat and is the main source of interface thermal resistance. High thermal conductivity paste or welding can fill the microscopic gaps, replacing the air and significantly reducing the thermal resistance.

d. Galvanic Corrosion Warning

Aluminum and copper can form a galvanic cell in the presence of an electrolyte, where aluminum, acting as the anode, will corrode. It is crucial to ensure the cooling system's integrity and use deionized water/anti-corrosion coolant to eliminate the corrosion path at the system level.

4-Surface Finishing (Skiving vs. Deep Burial)

Objective: To form the final cooling surface, which can be used for mounting chips, characterized by high flatness and low thermal resistance.

copper tubed cold plate from Walmate

a. Skiving Process: The Performance King

This process uses ultra-hard cutting tools to simultaneously cut both copper and aluminum, creating a perfectly co-planar and flush surface. This allows the heat source to achieve direct, large-area contact with the highly thermally conductive copper tube, resulting in the lowest possible thermal resistance.

b. Deep Buried Tube Process: The Reliability Guardian

This process involves embedding round copper tubes and filling the gaps with high thermal conductivity epoxy resin. The copper tubes retain their circular shape, offering greater pressure-bearing capacity. The filler material provides additional protection and stress buffering, leading to higher reliability, although the thermal resistance is slightly higher than that achieved by skiving.

c. Final Wall Thickness: The Lifeline

The core control objective of the skiving process is the final remaining wall thickness of the copper tube. A balance must be struck between performance (requiring thin walls) and reliability/prevention of cutting through (requiring thick walls). This thickness is typically controlled within the golden range of 0.15-0.3 mm.

d. Flatness: The Guarantee of Contact

Regardless of the process used, the flatness of the mounting surface (typically required to be <0.1 mm) is a mandatory specification. Micron-level variations must be filled with thermal grease. Poor flatness will lead to a sharp increase in contact thermal resistance, resulting in cooling failure.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

To enhance the range and capacity of electric vehicles, Power Battery Packs are transitioning from single-layer layouts to Multi-layer Stacking Structures. This shift significantly improves Energy Density, while also introducing entirely new structural challenges. This article will explore three aspects: core challenges, mainstream solutions, and future technological directions.

1-Core Challenges: Mechanical Challenges of Multi-layer Stacking

Expanding Battery Packs from a single layer to Multiple Layers is far from simple stacking. It reshapes the internal mechanical environment and external Load Paths, presenting four core challenges:

a.Vertical Load Surge and Material Creep Risk

・In Multi-layer Structures, the weight of Cells, Modules, and Structural Components accumulates layer by layer. The Static Compressive Load borne by the bottom layer is significantly higher than that of the top layer.

・This sustained High-Stress environment poses severe tests to the Long-Term Performance of materials, particularly Anti-Creep Performance (the slow Plastic Deformation of materials under Constant Stress over time).

・If Interlayer Supports or Cell Fixation Components undergo Creep, it may lead to Preload Relaxation, affecting Cell Cycle Life and Interface Contact Stability. Therefore, identifying materials that combine Lightweight properties with excellent Anti-Creep Characteristics is crucial.

b.Expansion ForceStacking Effect and Structural Stability

・Lithium-Ion Batteries experience a "Breathing Effect" during Charging and Discharging due to Volume Changes in Electrode Materials, leading to Cell Expansion. In Multi-layer Stacking Structures, Expansion Forces accumulate layer by layer, causing the bottom-layer Modules to withstand enormous pressure.

・This Cyclic Stress can easily trigger Casing Bulging, Seal Failure, Structural Component Compression, Cell Short Circuits, and accelerated Battery Performance Degradation. Effective control requires Built-in Sensors for Real-Time Monitoring combined with Digital Simulation to guide Structural Optimization Design.

c.Core Contradiction Between Space Utilization and Energy Density

・Addressing Gravity and Expansion Forces requires Reinforced Structures (such as adding Crossbeams or thickening Plates), but this occupies valuable space and increases weight, conflicting with the core goals of improving Volumetric Energy Density and Gravimetric Energy Density.

・The solution lies in Structural Optimization and the application of Efficient Materials, driving the transition of Battery Packs towards Multi-Material Hybrid Designs.

d.Collision LoadTransfer Path and Safety Redundancy Upgrade

・The Increased Height of Battery Packs intensifies Mechanical Loads during Side Impacts or Bottom Impacts; the Heightened Structure amplifies the Lever Effect, placing higher demands on Connection Point Strength and the Battery Pack's Own Stiffness.

・The use of Impact-Resistant Materials and Integrated Design is necessary to optimize Force Transfer and Energy Absorption, ensuring Cell Safety under Extreme Conditions, thereby promoting the development of Cell-to-Body Integration (CTC) technology, making the Battery Pack an integral part of the Vehicle Body Structure.

2- Comparative Analysis of Mainstream Structural Solutions

To address these challenges, the industry has explored various innovative solutions:

a.One-Piece Die-Cast Tray

・Advantages: High Integration, reduced Part Count, improved Overall Stiffness, Consistency, and Sealing. The Process supports Complex Geometries, facilitating the integration of Cooling, Reinforcing Ribs, and Mounting Points. The Monolithic Structure helps manage Complex Stresses.

・Challenges: Integral Die-Casting of Multi-Layer Frames imposes extremely high demands on Equipment, Molds, and Processes, making it costly. Post-Collision Repair is difficult or impossible. The Monolithic Rigid Structure may lack the Flexibility to manage Differential Expansion Forces between Layers.

b.Multi-Level Frame Modular

・Advantages: Flexible Design and Manufacturing, facilitating Production, Maintenance, and Replacement. Naturally suited for Multi-Material Hybrid Designs, allowing optimization of Performance and Cost for different Levels. Drawing on the "Quasi-Isotropic Lamination" concept of Composite Materials to optimize Overall Mechanical Response and disperse Stress.

・Challenges: Numerous Components and Connectors, Complex Assembly, Accumulated Tolerances affecting Precision and Preload. Numerous Connection Interfaces (Bolts, Rivets) are Potential Failure Points and add weight.

c.Hybrid Material Sandwich Structure

・Advantages: Excellent Lightweight Efficiency and extremely high Specific Stiffness (High-Strength Panels + Lightweight Core Materials such as Foam/Aluminum Honeycomb). Strong Bending Resistance, with Core Materials offering both Thermal Insulation and Energy Absorption Characteristics, enhancing Thermal Safety and Collision Safety. Aligns with the trend of Multi-Functional Integration.

・Challenges: Complex Manufacturing Process and high cost. The Interfacial Bond Strength and Long-Term Durability between Panels and Core Materials are critical. Core Materials must possess excellent Compressive Creep Resistance.

d.Bionic Honeycomb Structure

・Advantages: Theoretically an ideal Bionic Design (mimicking the HexagonalHoneycomb) for achieving Ultimate Lightweight, High Stiffness, and Compressive Strength. Provides Uniform Support with strong Impact Energy Absorption Capability.

・Challenges: Extremely complex Manufacturing and high cost, with significant Integration Difficulty with Cooling Systems etc. Currently primarily in the Frontier Research stage, requiring more time for large-scale Commercial Application.

3- Key Technological Breakthrough Directions

Future key breakthroughs in solving the Design Challenges of Multi-layer Stacking lie in:

a.Material and Process Innovation for Lightweight and Stiffness Balance

・Materials: Continuous optimization of CFRP, Aluminum Alloys, Magnesium Alloys; development of new Multifunctional Polymers and Composite Materials combining Low Creep, High Insulation, Good Thermal Conductivity, and Easy Processability.

・Processes: Development of Advanced Connection Technologies (Resistance Spot Welding, Laser Welding, Ultrasonic Welding) to achieve reliable, lightweight Multi-Material Connections.

b. Adaptive Management of Expansion Forces

Shifting the approach from "Rigid Resistance" to "Flexible Adaptation", creating Dynamic Response Systems to keep Cells in the Optimal Stress Environment throughout their Lifecycle.

Figure 1: Robotic laser welding of battery trays

c.Interlayer Connection and Integration Revolution

・Connection Technologies: Evolution from BoltMechanical Connections to Structural AdhesiveBonding and Advanced Welding for more uniform Stress Distribution, Good Sealing, and Fatigue Resistance.

・Ultimate Integration: CTC/CTB (Cell-to-Chassis/Body) is an important future direction for Battery PackIntegration. By eliminating Independent Housings and directly integrating Cells or Modules into the Chassis, the Multi-layer Stacking itself becomes a Vehicle Body Structural Component (such as Crossbeams or Floors), fundamentally solving Space Constraints and maximizing Battery Structural Functionality. Achieving this technology requires Deep Collaboration across multiple fields including Batteries, Structures, Thermal Management, and Safety, representing the Ultimate Form of the "Structure as Function" concept.

Figure 2: EV Battery tray

Multi-layer Stacking is an inevitable choice for increasing BatteryEnergy Density, but it also brings enormous challenges in Structure, Expansion Forces, and Safety. The solution lies in Material Innovation, Bionic Structural Optimization, and Intelligent Management of Expansion Forces. Ultimately, Battery Packs will Deeply Integrate with Vehicle Bodies, becoming an integrated "Energy Chassis".

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

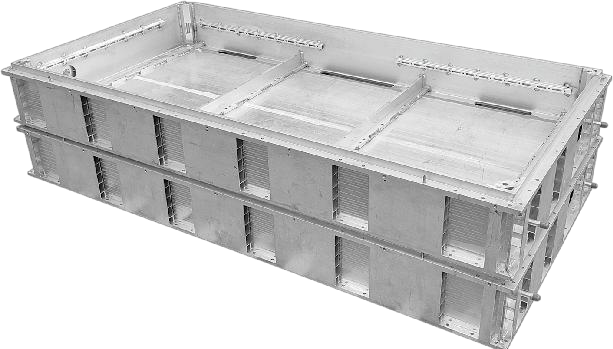

Two Core Challenges of Electric Heavy-Duty Trucks: In-Depth Analysis of Battery Layout and Stacking Technology

When a fully loaded electric heavy-duty truck travels on highways, the secret to its hundreds of kilometers of range lies within its chassis and battery compartment. As the wave of heavy-duty truck electrification sweeps the global logistics industry, the layout and stacking technology of battery systems have become critical to market success.

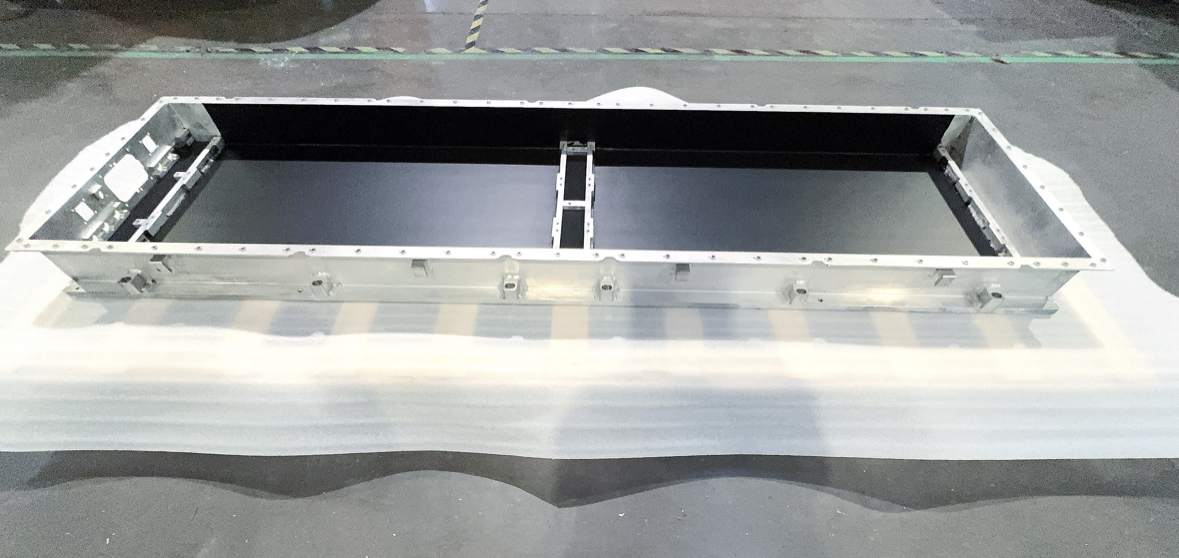

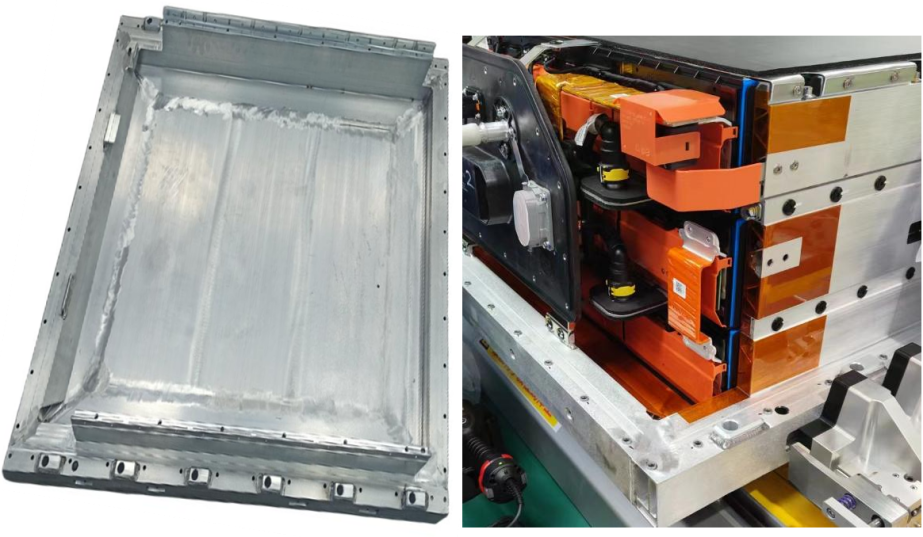

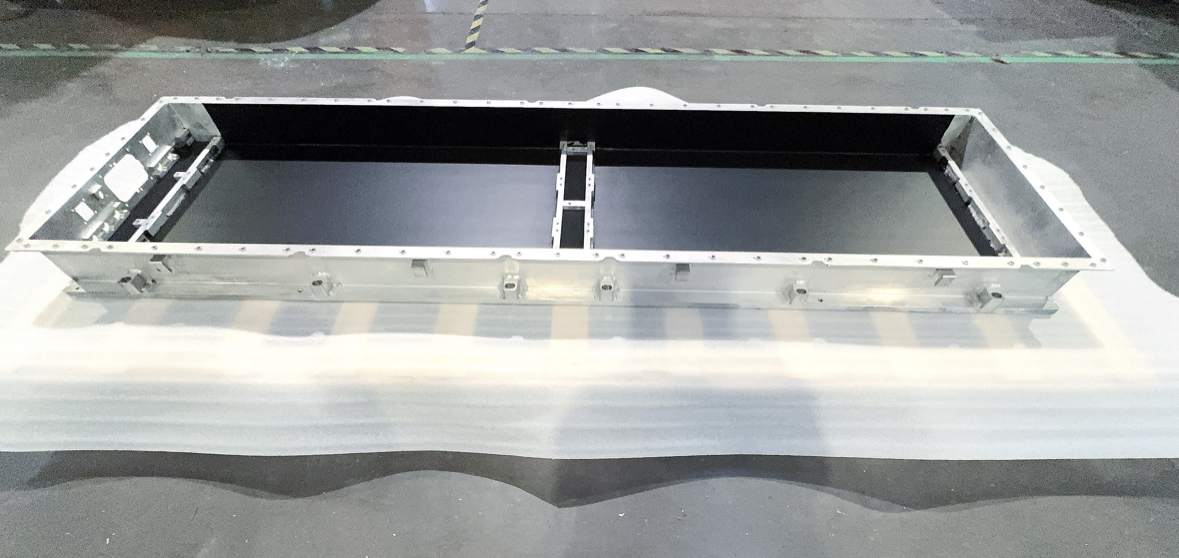

Figure 1: Liquid Cooling Solution for Electric Heavy-Duty Truck Batteries

1-Battery Layout: How Three Solutions Reshape Electric Heavy-Duty Trucks?

a. Back-Mounted Layout: Agile Choice for Short-Distance Transport

· Scenario: Short-haul operations in enclosed areas like ports, mines, and steel plants.

· Core Advantage: Rapid battery swapping (specific times require validation), improving vehicle utilization.

· Limitations: Battery capacity constraints (<350 kWh industry standard), high center of gravity affecting stability.

· Space Trade-off: Occupies cargo or cabin space, reducing load capacity.

b. Chassis-Mounted Layout: Endurance King for Long-Haul Transport

· Capacity Breakthrough: Battery capacity exceeds 500 kWh (e.g., disclosed 513 kWh solutions).

· Space Efficiency: Maximizes chassis space, avoiding cargo encroachment.

· Safety: Ultra-low center of gravity enhances high-speed stability.

· Technical Barriers: Chassis integration demands higher protection and thermal management.

c. Bottom-Side-Mounted Layout: Efficiency Engine for Battery Swap Networks

· Innovation: Lateral battery swapping boosts operational efficiency.

· Space Balance: Preserves full cargo space, with range between back and chassis layouts.

· Safety Focus: Requires reinforced side-impact protection structures.

2-Stacking Technology: Efficient Integration Solutions for Truck Battery Packs

Multilayer stacking is key to improving energy density:

Figure 2: Stacked Liquid Cooling Integration Box for Heavy-Duty Trucks

a. Frameless Integrated Stacking:

· Direct cell stacking reduces structural components.

· Eliminates modules/frames, enabling "Seamless Z-Stacking".

· Significantly boosts system energy density.

· Supports ultra-fast charging (performance requires validation).

b. Module-to-Chassis Integration (e.g., MTB/CTC):

· MTB: Modules directly connect to the frame, improving volume utilization.

· Qilin Battery(CTP 3.0): 72% volume utilization, 255 Wh/kg energy density.

· CTC: Cells integrate into the chassis, reducing weight by 10%.

c. Cell Form Innovation (e.g., Blade Battery):

· Flat cells tightly arranged, increasing volume utilization (>50% per BYD data).

· Breaks LFP energy density bottlenecks.

3-Core Technical Challenges

Challenge 1: Structural Safety

· Extreme Conditions: Side-pole collisions threaten side-mounted layouts.

· Solutions: High-strength aluminum alloy housings + buffers; FEA collision simulation; super-national mechanical impact tests.

Challenge 2: Thermal Management

· Critical Issue: Temperature differential control within packs is vital.

· Innovations: Lateral liquid cooling(<3°C differential); direct refrigerant cooling; MPC dynamic control.

Challenge 3: Vibration Fatigue

· Hidden Risk: Road vibration causes structural damage.

· Strategies: Z-stacking optimizes stress distribution; road spectrum vibration testing; high-damping materials.

4-Current Development Trends

· Chassis-mounted layouts dominate medium/long-haul: High range (>500 kWh) and low center of gravity are preferred.

· CTC integration fuses batteries with chassis, improving space utilization and rigidity.

· AI-driven thermal management enables precise temperature control (<5°C differential), extending battery life.

· Semi-solid-state batteries accelerate commercialization, focusing on safety and energy density.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

The wave of electric heavy-duty trucks is sweeping across the global logistics and transportation industry, injecting strong momentum into the "dual-carbon" goals. However, with the soaring demand for extended range, battery systems with single-pack capacities exceeding 500kWh or even approaching 1000kWh have become commonplace. This is akin to equipping vehicles with a mobile "energy fortress," but the potential thermal safety risks have also reached unprecedented levels. When the three extreme safety indicators—"ultra-large capacity," "ultra-fast thermal propagation" (<2 minutes), and "ultra-high collision resistance" (>1500kJ)—converge, the industry faces a severe technological gap. This article analyzes these challenges and explores systematic solutions to build a dedicated safety defense line for electric heavy-duty trucks.

Figure 1: Short-Blade Three-Layer Stacking Solution

1-The 500kWh+ Era: Opportunities and Safety Challenges Coexist

a. Capacity Leap Has Become the Norm

To meet the demands of heavy-load, long-distance transportation, the battery capacity of electric heavy-duty trucks has rapidly increased from 200-300kWh to 600kWh+. Industry leaders have rolled out solutions ranging from 500kWh and 600kWh to even 1000kWh, marking the official arrival of the ultra-large-capacity era.

b. The Maturity of LFP (Lithium Iron Phosphate) Battery Technology

LFP batteries have become a major driver due to their advantages in safety and cycle life, making them the mainstream choice for heavy-duty trucks.

2-The "Three Major Challenges" Under Extreme Safety Demands

a. Thermal Propagation Limit Control (<2 Minutes)

· Core Objective: Safety designs must delay or block thermal propagation to create a time window for evacuation and rescue (e.g., the 5-minute early warning requirement under China's GB 38031-2020 standard).

· Harsh Reality: In high-density battery packs exceeding 500kWh, the massive energy released by a single cell during thermal runaway can easily trigger a catastrophic chain reaction. Test data shows extremely rapid thermal propagation: in some cases, it takes only 22 seconds to engulf the entire pack, 5 seconds to ignite adjacent modules, and as little as 44 seconds for inter-module propagation.

· Core Difficulty & Gap: How to effectively ensure inter-module thermal propagation is controlled beyond 2 minutes? Currently, no commercial heavy-duty truck system has publicly claimed or verified compliance with this stringent requirement.

b. Structural Collision Resistance Barrier (>1500kJ)

· Core Requirement: The collision energy of a fully loaded heavy-duty truck far exceeds that of passenger vehicles, easily surpassing 1500kJ. As a structural component of the chassis, the battery pack must possess ultra-high strength to remain intact post-collision, preventing internal cell damage that could lead to thermal runaway.

· Harsh Reality: Current domestic and international standards (e.g., GB/T 31467.3-2015, UNECE R100) lack clear or sufficient thresholds for collision energy testing of heavy-duty truck battery packs. Publicly available certification data for systems passing 1500kJ-level collision tests is extremely scarce. Although higher-energy simulations exist (e.g.,2500kJ), full-system validation remains a significant challenge.

· Core Difficulty & Gap: The absence of clear high-energy collision protection standards and thoroughly validated solutions.

c. Secondary Disaster Chain Risks (Cargo Explosion & Road Paralysis)

· Cargo Explosion Risk: High-temperature flames from battery thermal runaway can easily ignite cargo (especially hazardous materials), forming a disaster chain: "battery runaway → cargo fire → explosion."

· Road Paralysis Risk: Lithium battery fires are difficult to extinguish (requiring large volumes of continuous cooling water) and prone to reignition. A multi-ton heavy-duty truck catching fire on a highway or in a tunnel complicates rescue efforts (high-voltage power cutoff, toxic gas prevention) and takes an extended time (up to several hours, with potential impacts lasting 24 hours), severely disrupting traffic and causing significant societal repercussions.

· Core Difficulty & Gap: The lack of targeted quantitative road clearance time standards and efficient emergency response systems.

3-Building the Defense Line: Thermal Event Early Warning System Design – Four-Layer Protection Net

4-Thermal Management Supporting Solutions: Empowering the Early Warning System

· Liquid Cooling System: Integrated high-efficiency liquid cooling plates eliminate localized hotspots, maintaining a temperature difference of <3°C between cells.

· Modular Design: Independently detachable module structures enable quick replacement of faulty units.

· Intelligent Monitoring Platform: Cloud-based real-time battery health analysis with automatic early warning alerts sent to maintenance teams.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

In the new energy heavy truck market, "battery stacking" has become a key term: mainstream models now exceed 370kWh in battery capacity, with 600kWh+ models frequently debuting. This is not just a leap in technical specifications but also the industry's declaration of a full-scale assault on the line-haul logistics market—by enhancing single-charge range, addressing the core user pain point of "range anxiety," and optimizing total cost of ownership (TCO). This article will dissect the business logic and technological breakthroughs behind this trend.

1-Business Logic: Why Must We "Stack Batteries"?

a. Scenario-Driven Necessity

·Closed Scenarios (Short-Distance, High-Frequency): Ports, mines, and similar settings rely on battery-swapping models (3-5 minute recharge), where 280kWh batteries suffice.

·Line-Haul Logistics (Long-Distance Transport): Accounts for 70% of freight volume, requiring a single-charge range of 500+ km. 600kWh+ batteries serve as the "gateway" to this market.

b. The Economics of TCO

Key Conclusion: When daily mileage exceeds 300 km, the TCO of battery-swap heavy trucks begins to outperform diesel trucks.

b. Model Innovation: Resolving Cost Challenges

·Battery-as-a-Service (BaaS): Users purchase the "bare vehicle" with battery leased monthly (¥5,000–9,000), reducing upfront costs by 30%.

·Battery Swap Services: Service fee of ¥0.2–0.5 per kWh, with total energy costs around ¥2.73/km (close to diesel trucks at ¥2.8/km).

·Commercial Validation: A swap station serving 50 vehicles/day can shorten the payback period to 5 years (IRR of 13.1%).

2-Technological Breakthroughs: How to Balance Range and Weight?

a. Spatial Compromise: Chassis for Space

·To prevent batteries from encroaching cargo space, the industry is optimizing battery layout. For example, integrating batteries into the chassis (replacing traditional rear-mounted designs) frees up cargo volume, lowers the center of gravity, and may improve energy efficiency.

·Trade-off: Reduced ground clearance and compromised chassis modularity.

b. Material Science Compromise: Energy Density for Weight

·The key to weight reduction lies in improving battery energy density (more energy stored per unit weight). Higher density enables lighter batteries or extended range at the same weight.

·Core Innovation: Battery materials (e.g., high-nickel cathodes, silicon-carbon anodes).

·Trade-off: Higher energy density often comes with safety risks, shorter lifespan, increased costs, and reduced fast-charging capability—requiring difficult multi-parameter balancing.

c. Business Model Compromise: Network Over Single-Vehicle Pressure

·The battery-swap model shifts the "infinite range" burden from individual vehicles to the swap network. By deploying dense swap stations along routes, trucks only need enough charge to reach the next station, eliminating oversized batteries.

·Outcome: Reduces extreme battery capacity demands, making onboard battery loads more "rational."

d. Residual Value Management: The Core Barrier for BaaS

Battery banks must develop full lifecycle capabilities: State-of-Health (SOH) monitoring, cascading reuse, and recycling systems.

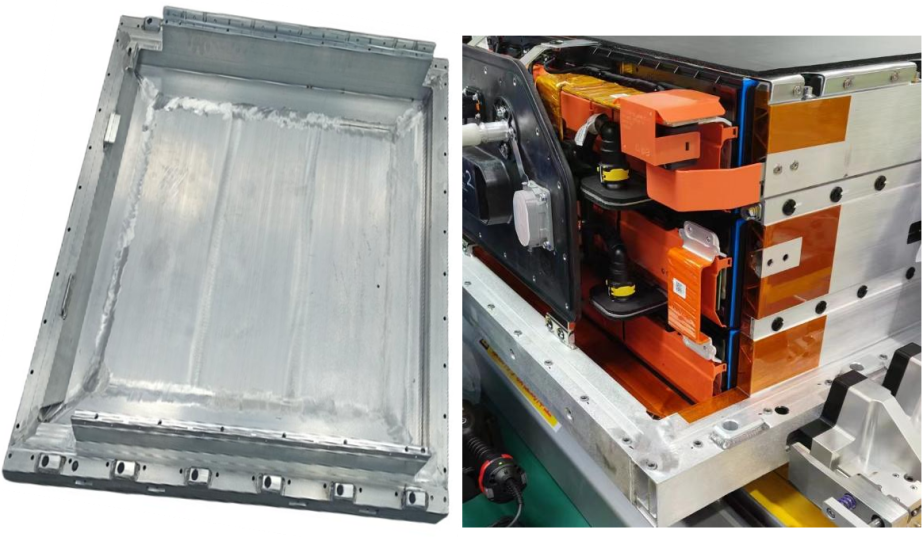

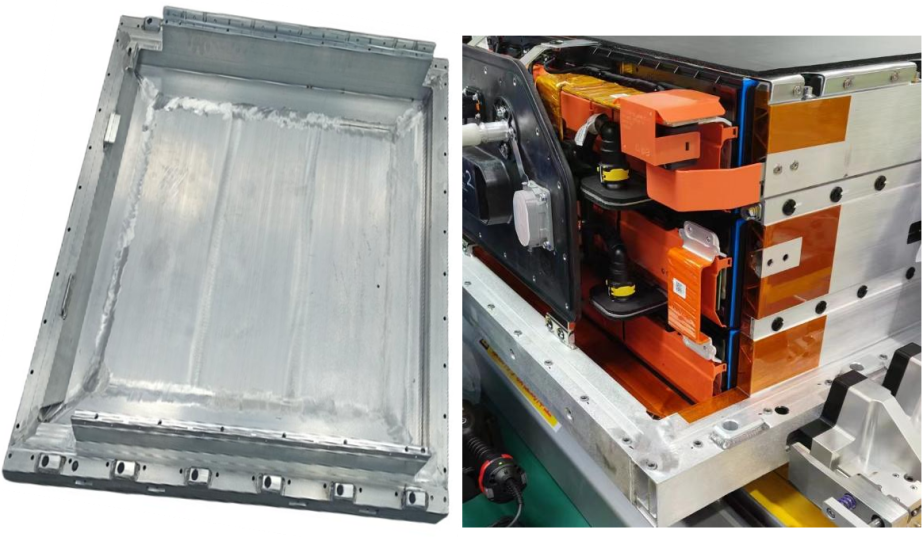

Figure 1: Heavy-duty truck battery pack enclosure

3-Future Trends: From "Battery Stacking" to "Efficient Energy Loading"

a. Technology Evolution: Solid-state batteries will break energy density barriers, rebalancing weight and range.

b. Charging Infrastructure: Standardized heavy-truck swapping protocols and grid synergy (e.g., peak shaving) are critical for scale.

c. Multi-Path Competition: Hydrogen-powered heavy trucks retain substitution potential in long-haul, heavy-load segments.

Conclusion: Phased Strategy, Long-term Evolution

"Battery stacking" is an inevitable choice for electric heavy trucks to conquer line-haul logistics, reflecting a dynamic balance between commercial needs and technical realities. As battery technology advances and business models mature, the industry will shift from a "capacity race" to an "efficiency race." Currently, it is driving China's new energy heavy trucks to complete the critical leap from "niche" to "mainstream."

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

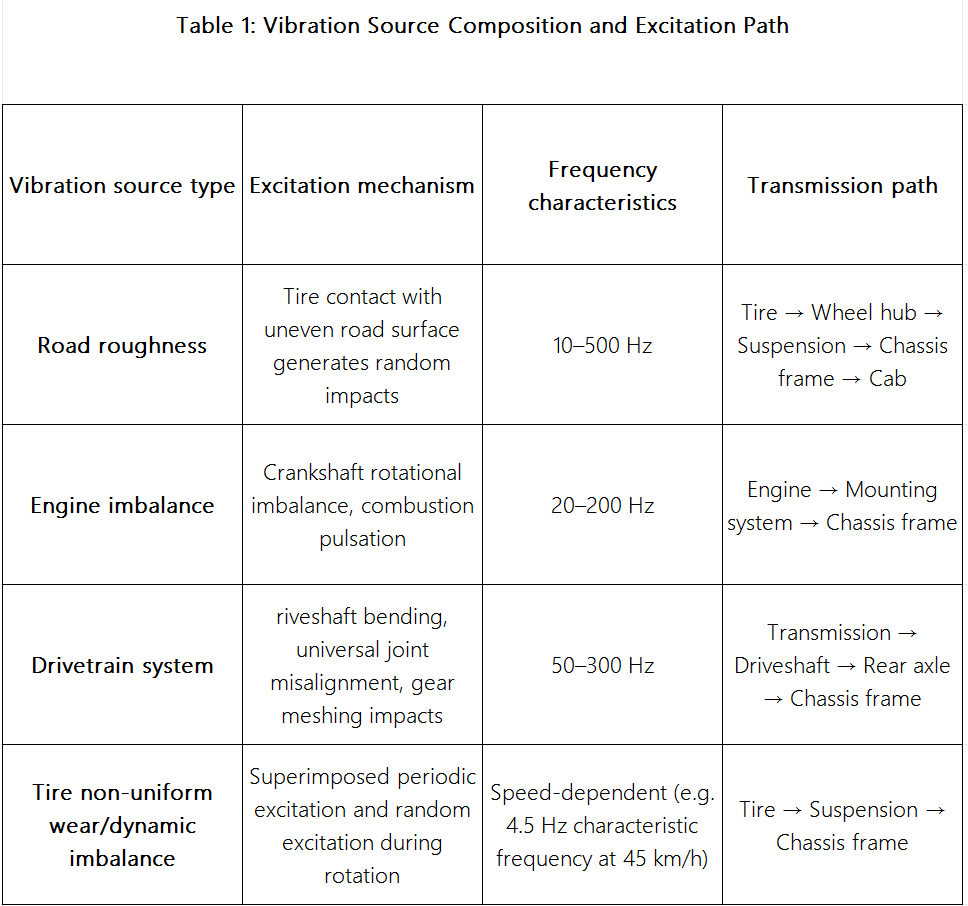

Core of Thermal Management for Heavy-Duty Truck Battery Packs: Dual Breakthroughs in Lightweight Materials and Manufacturing Processes

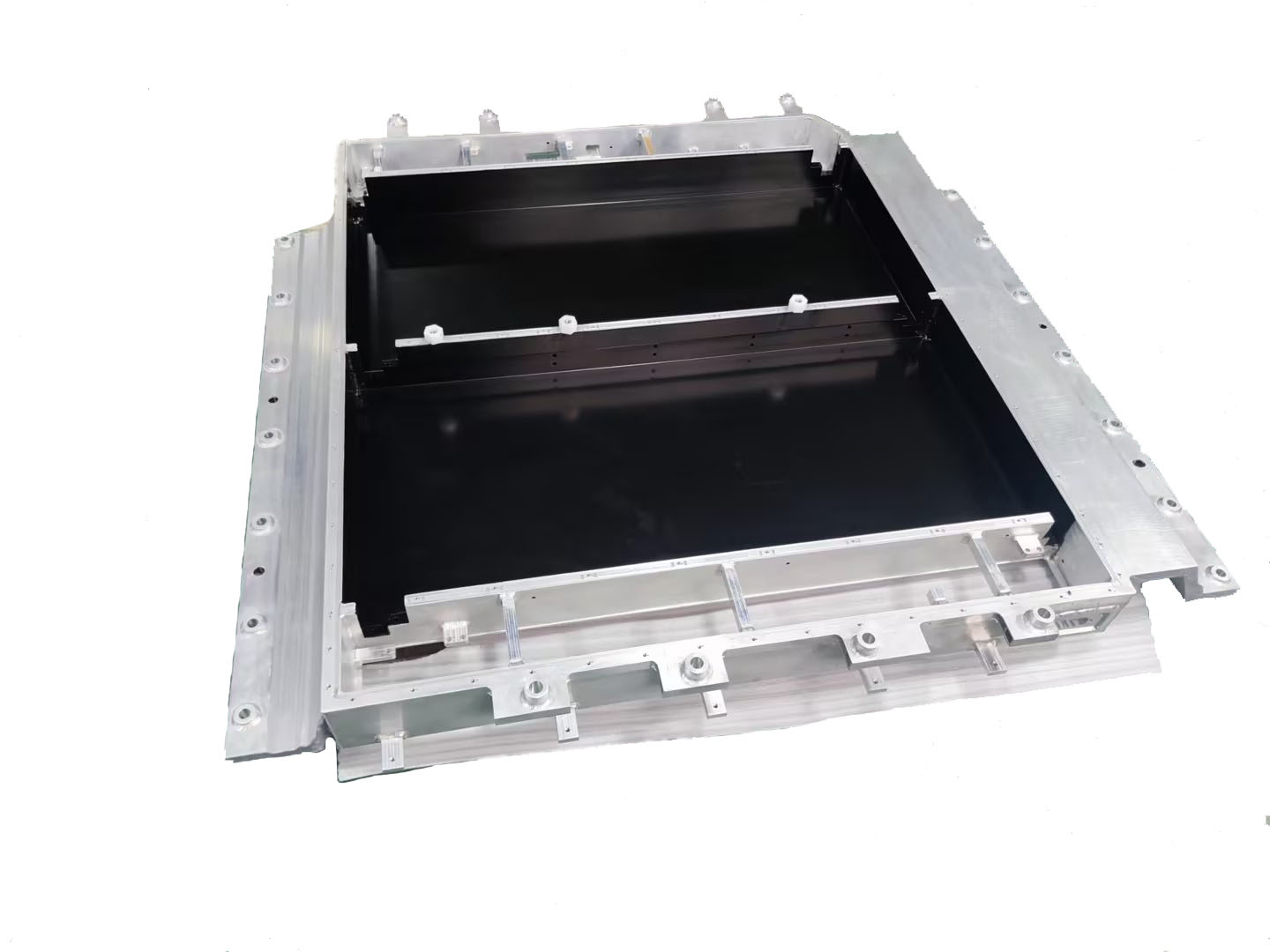

Heavy-duty trucks (HDTs), as the core force in road logistics, have made the safety, reliability, and cost-effectiveness of their battery systems a key technological focus. The battery tray, as the critical structural component that carries, protects, and manages battery modules, is now facing unprecedented extreme challenges.

Figure 1: Battery tray for electric heavy-duty trucks

1-Extreme Challenges for Heavy Duty EV Battery Tray

a. Stringent Mechanical Durability Requirements: Vibration, Impact, and Million-Kilometer Service Life

Heavy-duty trucks are designed with a service life of ≥1.5 million kilometers, 10 times longer than that of passenger vehicles. The battery tray must continuously withstand the following three types of extreme mechanical loads throughout its entire lifecycle:

·High-frequency random vibrations: When fully loaded and driving on unpaved, construction, or uneven roads, the chassis generates random vibrations across a wide frequency band (5 Hz–2 kHz). These vibrations not only test the fatigue limit of the tray's main frame but also induce microcracks in stress concentration zones such as welds, bolt holes, and flanges, becoming potential failure initiation points.

·High-g transient impact: Deep potholes, emergency braking, or handling drops can generate impact accelerations exceeding 50 g within milliseconds. The tray must instantaneously absorb/dissipate energy to prevent cell displacement, short circuits, or casing rupture.

·Cumulative fatigue damage: A million-kilometer service life means hundreds of millions of vibration cycles. Under alternating stress, aluminum alloys are prone to fatigue crack initiation and propagation, eventually leading to structural fracture. The core design task is to delay crack initiation until after the vehicle's retirement through topology optimization, local reinforcement, hybrid material integration, and process control.

b. Complex Thermal Management and Thermal Cycling Challenges

Due to their ultra-high capacity (hundreds of kWh) and high-power charging/discharging, heavy-duty truck battery packs generate massive heat. They also operate across arctic to tropical environments, facing extreme temperature differentials.

·Wide-temperature-range control: The tray and thermal management system (TMS) must precisely maintain cell temperatures within the optimal 25–40°C range under ambient temperatures ranging from -40°C to +85°C, with <5°C temperature variation between individual cells.

·High-stress thermal cycling: In accelerated aging tests, the system must endure thousands of -40°C ↔ +85°C thermal shock cycles (ramp rate: 5–15°C/min, dwell time: 5–15 minutes). This process causes repeated thermal expansion/contraction at material interfaces (aluminum alloy/sealant/plastic components), posing severe challenges to the reliability of welded/adhesive joints in integrated cooling channels.

2-Mainstream Material Solutions and Multi-Functional Integration Technologies

To address these challenges, the industry has developed a technology roadmap based on high-strength aluminum alloys, evolving toward highly integrated multi-functional designs.

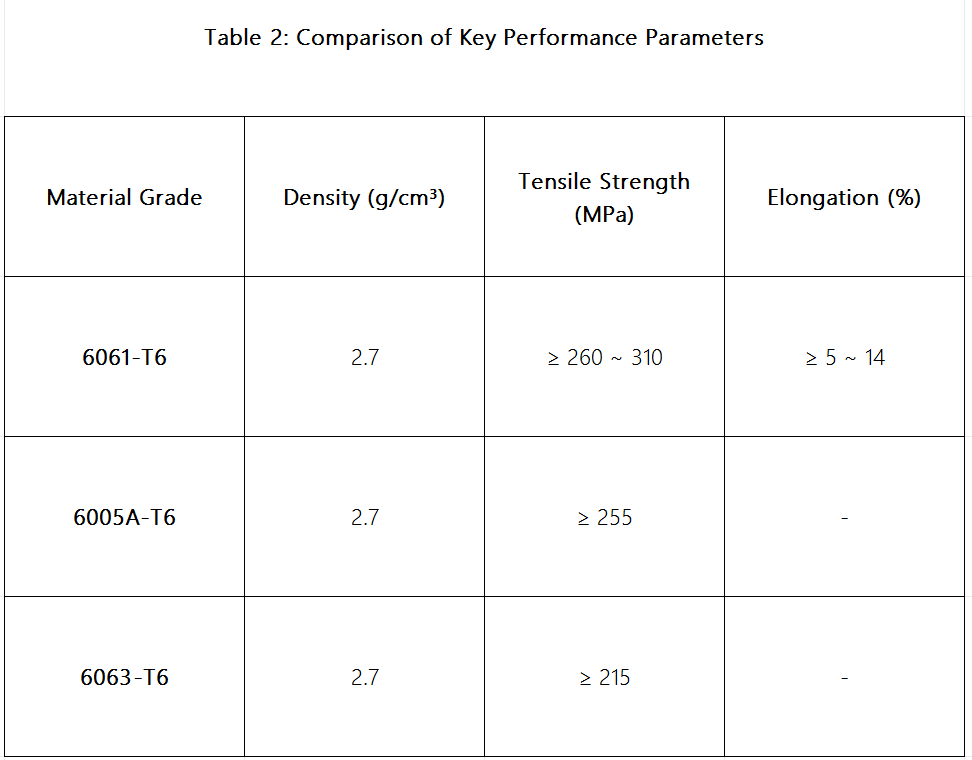

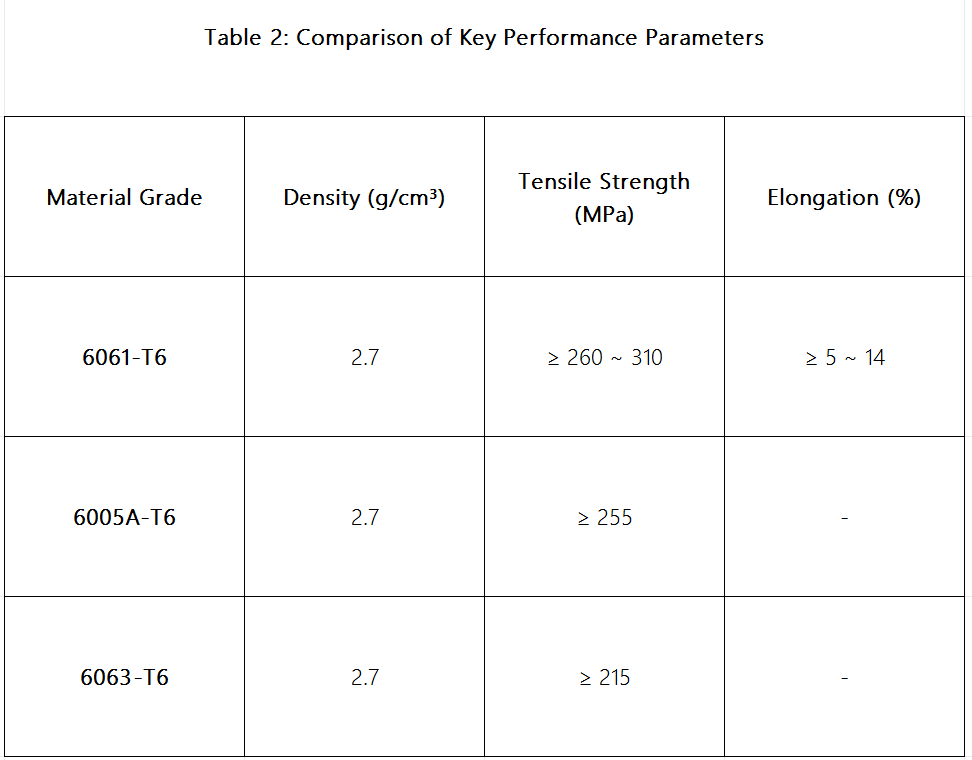

a. Core Material Selection: The Dominance of 6xxx-Series Aluminum Alloys

In competition with steel, magnesium alloys, and composites, 6xxx-series (Al-Mg-Si) aluminum alloys have become the mainstream material for heavy-duty truck battery trays due to their excellent comprehensive performance, mature processing techniques, and high cost-effectiveness.

Key Alloy Grades and Properties:

·6061-T6: The most widely used grade, renowned for its outstanding strength, good weldability, and corrosion resistance.

·6005A-T6 and 6063-T6: Supplementary options, also offering good extrudability, suitable for components with slightly lower strength requirements.

b. Paradigm Shift in Design Philosophy: Thermal Management and Structural Health Monitoring

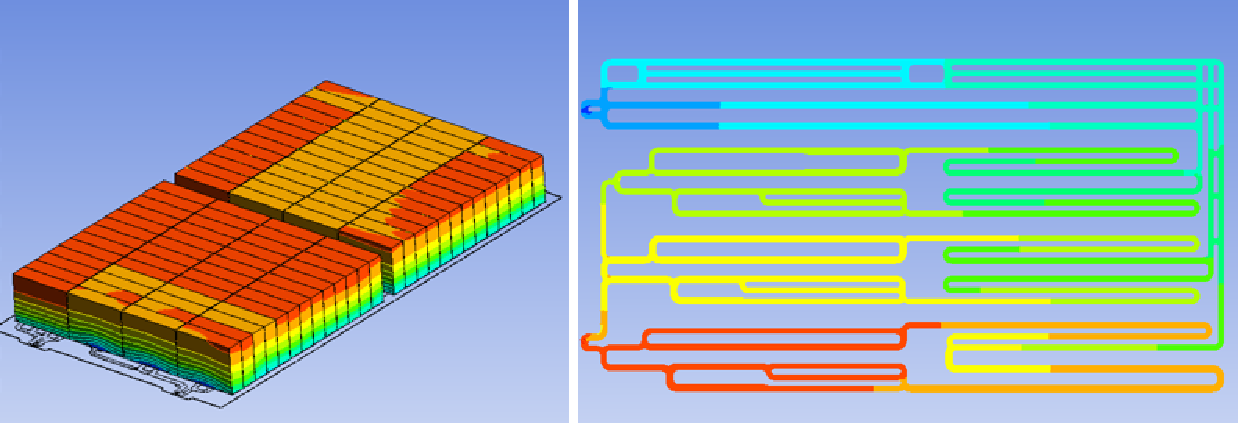

The design philosophy of modern heavy-duty truck battery trays has undergone a fundamental transformation—evolving from a purely mechanical "load-bearing structure" to a highly integrated "intelligent thermal regulation platform." This shift is primarily manifested in two key technological directions:

·Integrated Thermal Management (Mature Application)

Currently the most technologically mature and widely adopted approach, its core concept involves embedding cooling functionality directly into the tray's structural design to achieve compact and efficient thermal regulation.

·Structural Health Monitoring (SHM) Exploration (Early Stage)

This emerging technology aims to preemptively detect potential structural damage (e.g., cracks, deformations) during long-term service. However, it remains in the validation and laboratory research phase, lacking large-scale commercial deployment cases or sufficient long-term operational reliability data.

3-Analysis of Core Manufacturing Process Routes

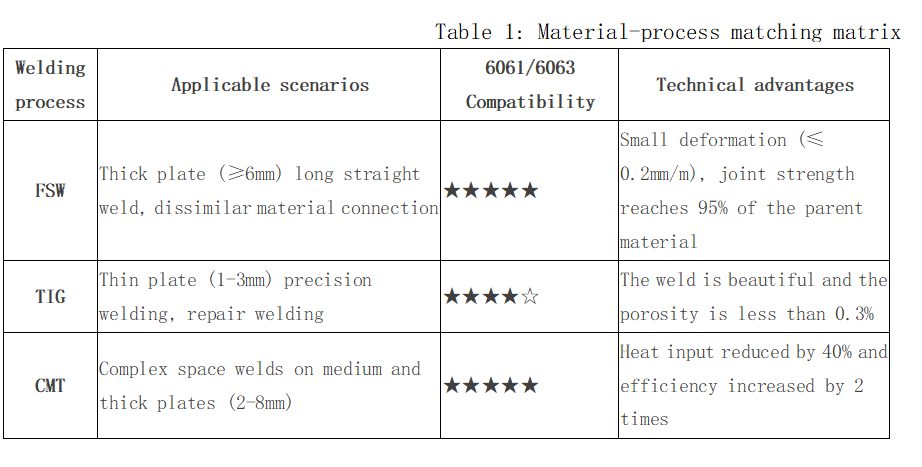

The manufacturing processes for heavy-duty truck battery trays directly determine their cost, performance, and production efficiency. The mainstream approach combines aluminum extrusion and friction stir welding (FSW), optimally balancing performance requirements with small-to-medium batch production models.

a. Aluminum Extrusion

This process shapes aluminum billets into elongated structural components (e.g., crossbeams, longitudinal beams) via dies. As the cornerstone technology for battery trays, it offers:

·Advantages: Low mold costs, short development cycles, and adaptability to large, non-standardized parts in small batches.

·Limitations: Requires cutting, machining, and multi-step welding assembly, resulting in low automation, slower cycle times, and inferior efficiency compared to integrated die casting.

b. Friction Stir Welding (FSW)

A solid-state joining technology, FSW generates heat via a rotating tool to achieve high-strength aluminum welds, making it the premier choice for load-bearing/sealed joints:

·Performance: Weld strength reaches 80–90% of the base material, with no porosity/cracking defects. Minimal thermal distortion ensures IP67+ sealing and eco-friendliness.

·Constraint: Limited to flat/simple-curved weld geometries.

Aluminum alloy heavy-duty truck battery trays have transcended their role as high-strength lightweight structures to become multifunctional integrated platforms. However, proliferating functionalities introduce challenges like multi-physics coupling failures, process complexity, and reliability risks. Future breakthroughs will hinge on material-process-system co-innovation, leveraging adaptive interfaces and digital twin technologies to enable the safe and sustainable evolution of intelligent trays.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.

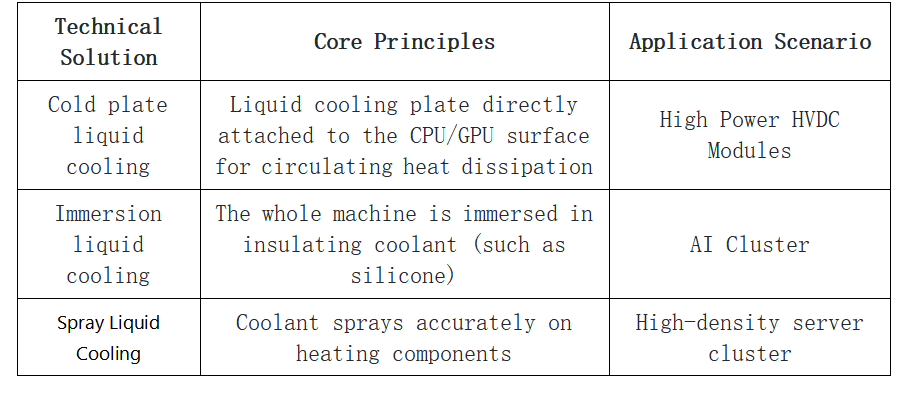

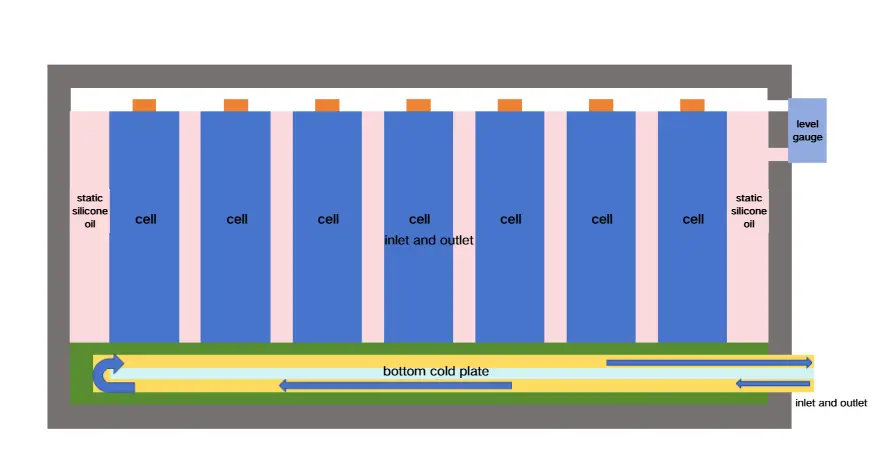

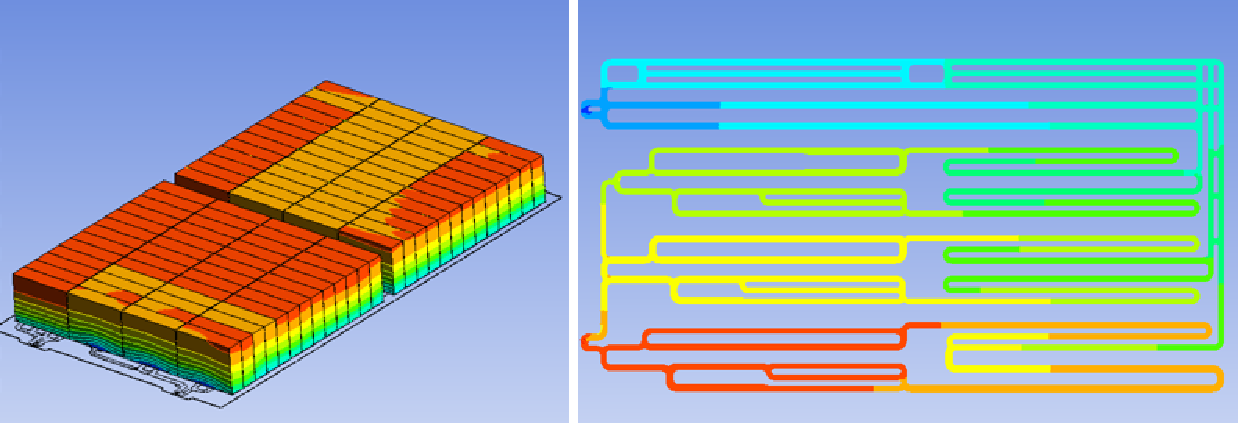

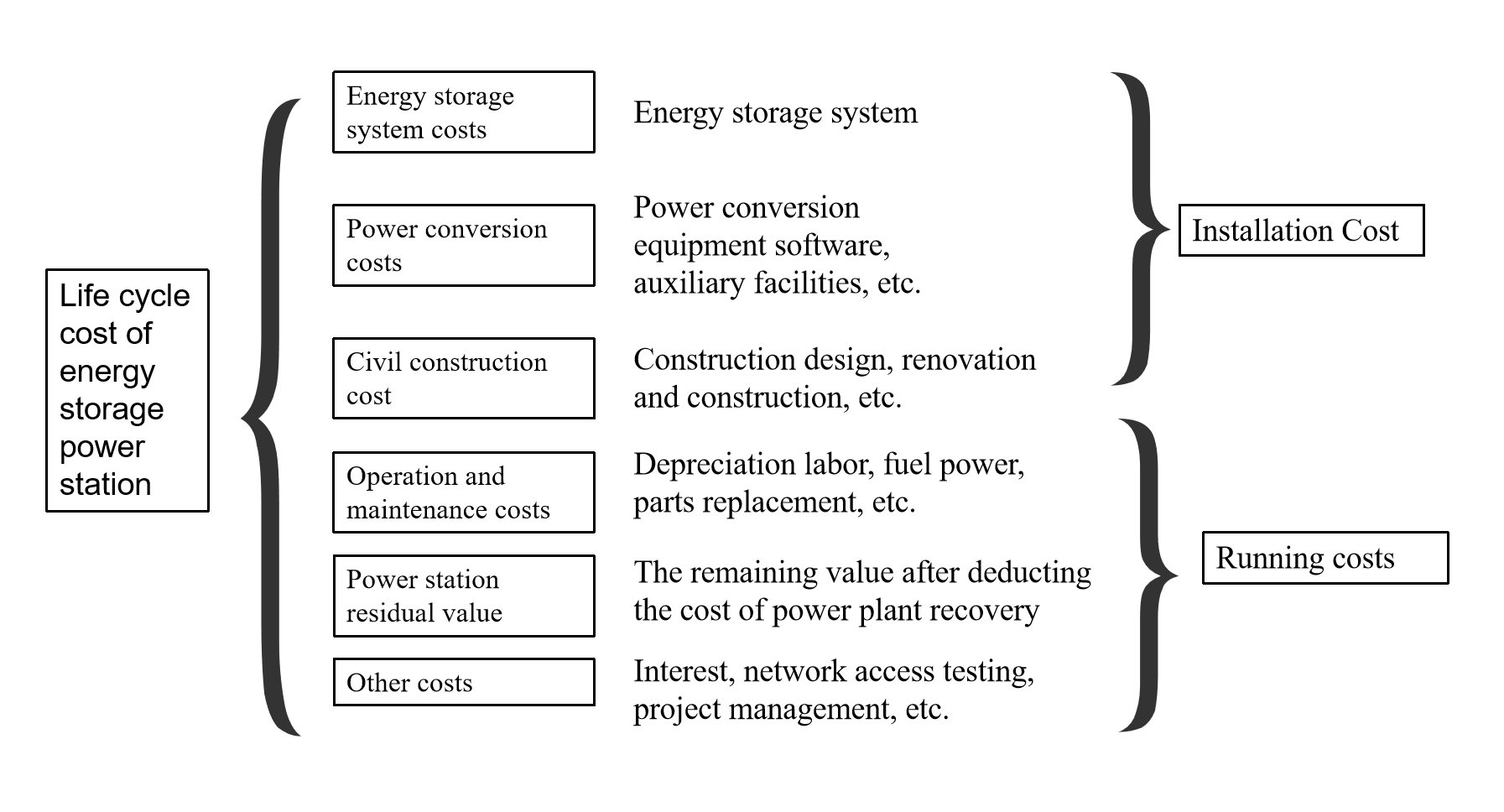

5 Optimization Guidelines for Energy Storage Liquid Cooling Plate Design Amid the 500Ah+ Large Battery Cell Wave

Cost-Driven Large Cell Revolution and Cooling Challenges:The energy storage industry is undergoing a profound transformation driven by "cost reduction and efficiency enhancement" – the rapid rise of the large cell technology roadmap. 300Ah+ cells are becoming standard, while 500Ah and even higher capacity cells are accelerating their deployment. While this revolution enhances system energy density and reduces per-watt-hour costs, it also presents severe challenges: a dramatic increase in individual cell mass, a surge in module/pack (battery pack) overall weight, multiplying the load-bearing pressure on bottom support structures; larger heat generation power and longer internal heat transfer paths impose extreme demands on the efficiency and uniformity of the thermal management system. As the core of pack thermal management, liquid cold plates face the brunt of the upgrade pressure.

Traditional "thin-plate covering" cold plate designs are no longer sustainable. Under constraints of limited space and stringent cost control, cold plates must transcend their single function of heat dissipation and evolve towards a trinity of "structural-functional integration, ultimate heat dissipation efficiency, and system lightweighting." This article will delve into this advanced design pathway.

1-Structural-Functional Integration: The "Load-Bearing Revolution" of Cold Plates

As cell mass significantly increases, the loads borne by the enclosure baseplate and the cold plate surge dramatically. Designing the cold plate as a load-bearing structural component is the key breakthrough point for resolving the conflicts between weight, cost, and space.

a.Becoming the Enclosure's "Skeleton": Integrated Load-Bearing Baseplate

Design Concept:The cold plate no longer attaches to the enclosure baseplate; instead, it becomes the primary load-bearing structure of the enclosure itself.

Core Advantages: Significantly reduces traditional baseplates and mounting brackets, markedly lowering system weight and material costs, and simplifying the assembly process.

Technical Requirements: Must demonstrate extremely high bending, compression, and impact resistance stiffness and strength.

b. Embedding "Steel Reinforcement": Topology Optimization and Reinforcement Structures

Mechanics-Led Design: Utilize CAE simulation for topology optimization, integrating stiffening ribs, etc., within non-critical heat dissipation areas of the cold plate (e.g.flow channel gaps, edges).

Efficient Material Utilization: Optimized design ensures material is distributed along critical stress paths, removing redundant material, achieving lightweighting while guaranteeing load-bearing capacity.

c.Module-Level Load-Bearing Platform: Consolidating Components

Large-scale, high-strength cold plates can directly serve as the mounting baseplate and load-bearing skeleton for modules. Cells or modules are fixed directly onto them, eliminating the need for additional support frames, further streamlining the structure and improving volumetric efficiency.

2-Significant improvement in heat dissipation performance: the art of balancing efficiency and equation

The core pain points of large battery cells are the difficulty in dissipating heat in the central area and controlling the overall temperature difference. The design of liquid cooled plates requires innovation from multiple dimensions including flow channels, interfaces, and materials.

a. Flow channel design: from "simple pipeline" to "intelligent blood vessel"

·Precise diversion and enhanced turbulence: Adopting a tree branch flow channel, serpentine+turbulence column/fin composite structure, to increase flow and disturbance in the high heat zone of the cell center. Avoid the "fast edge cooling and slow center cooling" caused by the straight path with large drift diameter.

·Variable cross-section and zone cooling: Based on the heat generation in different areas of the battery cell (such as center>edge), design gradient cross-section flow channels or independently controllable zone circuits to achieve precise and on-demand heat distribution, with temperature difference control up to ± 2 ℃.

·Biomimetic and Topology Optimization of Flow Channels: Utilizing CFD and topology optimization techniques to generate an efficient and low resistance "natural growth" flow channel network, maximizing heat transfer area and efficiency, and reducing pump power loss.

b. Breaking through interface thermal resistance: making "contact" tighter

·High performance interface material (TIM): research and develop high thermal conductivity (>5W/mK), low thermal resistance, long-term stable thermal conductivity gasket/gel/phase change material, and take into account insulation, cushioning and processability.

·Microstructure surface engineering: Processing micro grooves, array micro protrusions, or applying special coatings on the contact surface of the cold plate to increase the effective contact area, enhancing contact through capillary force, and significantly reducing interface thermal resistance (can be reduced by 30% -50%).

c. Material Upgrade: Dual Pursuit of Thermal Conductivity and Strength

Exploring higher thermal conductivity aluminum alloys (such as high thermal conductivity 6-series and specific 7-series alloys) or aluminum based composite materials (AMCs) while ensuring structural strength, to enhance basic thermal conductivity.

3-Lightweight throughout: a weight game where every gram is worth fighting for

Every gram of weight loss means reduced costs and improved transportation and installation efficiency.

Refined 'slimming' design:

a. Simulation driven thinning: Through precise CAE calculations, the maximum thinning of the cold plate wall thickness is achieved while meeting strength, stiffness, and heat dissipation requirements (such as reducing from 2.0mm to 1.5mm).

b. Hollow structure and hollow out: Design hollow cavities or perform safe hollow out treatment inside the reinforcing ribs and non critical areas.

c. Application of high-strength materials: Using higher strength aluminum alloys (such as 7xxx series) to achieve thickness reduction and weight reduction under the same performance.

4-Manufacturing process: the cornerstone supporting advanced design

The "structuring" and "complexity" of liquid cooled plates pose higher requirements for manufacturing processes.

Upgrading and integration of mainstream processes:

·Aluminum extrusion+Friction Stir Welding (FSW): advantages lie in large size and high structural strength. Advanced direction: Developing complex profile sections with integrated flow channels and reinforcing ribs; Breakthrough in ultra long and variable cross-section FSW welding technology to ensure weld strength and airtightness.

·Stamping+brazing: The advantage lies in flexible channel design and great potential for lightweight. Advanced direction: Achieving precision stamping of deeper and more complex flow channels; Improve the yield and joint reliability of large-sized and multi-parts-brazing; Integrate reinforced structures on stamped parts.

·High pressure die-casting: The potential lies in manufacturing highly integrated and extremely complex-shaped cold plates (with integrated flow channels, rib positions, and interface oneness) .Challenges such as mold cost, internal channel surface smoothness, and pore control should be overcome.

·Hybrid process innovation: Multi process combination innovation, integrating the advantages of different processes to meet more complex design requirements.

5-Reliability: the lifeline of integrated design

When the liquid cooled plate becomes the core of the structure, its reliability is related to the safety of the entire PACK.

Strengthen the dual reliability of "structure-fluid":