To Understand

Your Project Goals and Outputs

The development of electric vehicles is facing structural bottlenecks. The battery pack is no longer just a container—it must become the core structural component of the vehicle. We are acutely aware of the industry’s pain points:

The energy density dilemma: How can more energy be stored in limited space?

Thermal management pressure: How can the high heat generated by fast charging be effectively controlled?

Safety and reliability: How can resistance to challenges such as collisions and vibrations be ensured throughout the entire lifecycle?

We address these challenges through integrated structure and functionality. By deeply combining the load-bearing, heat dissipation, and protective functions of the battery pack, we create a structural system with higher energy density, enhanced safety and reliability, and more efficient production. This evolution transforms the battery pack from a "housing unit" into a "functional core," laying a solid foundation for the advancement of electric vehicles.

Electric Passenger Vehicles

Focused on range and user experience, we deliver highly integrated CTP solutions. Through ultra-lightweight design and efficient thermal management, we help alleviate range anxiety, support fast-charging demands, and maximize the value of every kilowatt-hour.

Electric Commercial Vehicles

Dedicated to lifecycle reliability, we build fortress-like structural solutions. With reinforced tray designs and optimized thermal management systems, we ensure safety and durability under high-intensity operations, providing trustworthy assurance for your business.

Through our professional solutions, each vehicle model can achieve a battery pack structural system that is optimally suited to its requirements.

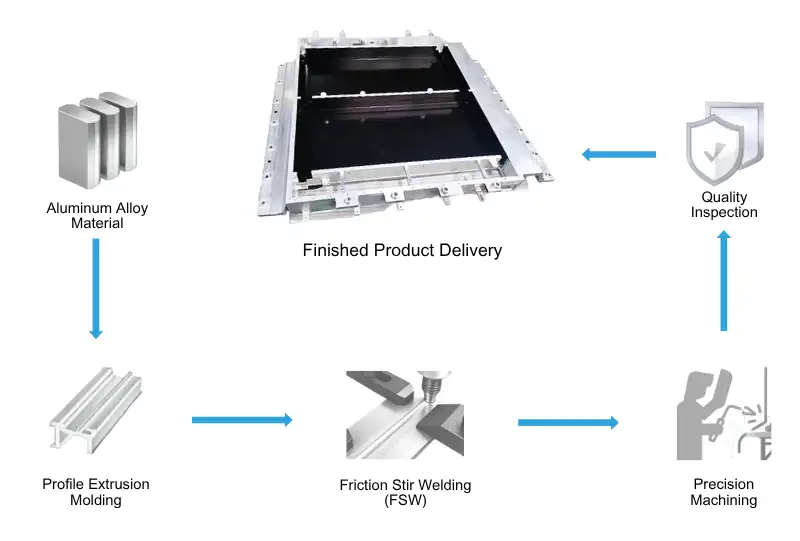

We master large aluminum profile monobloc extrusion, achieving deep integration of structure and function.

Integrated Channel Design

Precision extrusion enables unibody construction of base plates and cooling channels. This monolithic structure ensures channel integrity and continuity, providing a stable foundation for thermal management systems.

Superior Structural Performance

The extruded base features complete metallurgical flow lines, delivering excellent strength and rigidity. Precisely formed channels enable uniform coolant distribution, ensuring optimal heat dissipation.

We apply FSW to critical joints, ensuring superior connection quality in core structures.

Reliable Sealing

The process creates dense, uniform welds through material plastic flow, delivering high-performance sealing that meets stringent protection standards.

Stable Joint Quality

FSW produces welds with excellent mechanical properties—high joint strength and low defect rates. Its low heat input minimizes distortion and maintains dimensional accuracy.

Together with monobloc extrusion, these core processes form the technical foundation of our