To Understand

Your Project Goals and Outputs

By focusing on the "special needs" of diversified application scenarios, Maytec creates highly adaptable customized battery tray solutions through the trinity of material, structure and function collaborative innovation, providing safety protection, energy efficiency optimization and sustainable operation guarantee for energy storage systems, promoting the upgrading of energy structure in various industries and contributing to green and low-carbon development.

Structural modular reconstruction: From the perspective of material innovation, architecture design, process adaptation and other dimensions, the structural modular reconstruction is realized.

Scenario function integration: guided by scenario requirements, build a flexible system of "basic modules + scenario expansion" to meet the needs of energy storage battery pack segmentation scenarios.

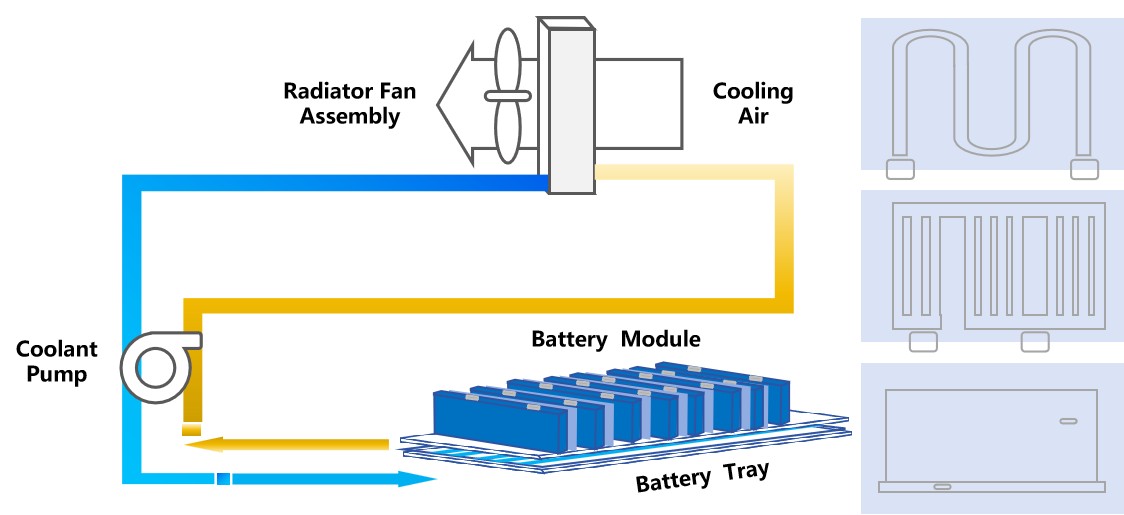

The battery features IP67-rated sealing protection to effectively block external environmental erosion and internal leakage risks. Its pressure-resistant structure ensures mechanical stability during static stacking and dynamic impacts. Precise positioning prevents stress concentration in cell assembly. These three synergistic constraints collectively provide systematic protection for the battery system, meeting intrinsically safe requirements.

By integrating innovative aluminum extrusion profiles with friction stir welding (FSW) technology, this solution delivers three core advantages: high-strength fusion welds (reaching 70% of base material strength), full enclosure sealing (IP54-rated enclosure and IP67-rated flow channels), and temperature-controlled precision welding deformation ≤2mm. These innovations collectively enhance structural integrity, environmental protection, and dimensional accuracy, establishing a fundamentally safe foundation for battery systems.