Communication and sharing promote growth

Joining Hands for Development!

Two Core Challenges of Electric Heavy-Duty Trucks: In-Depth Analysis of Battery Layout and Stacking Technology

When a fully loaded electric heavy-duty truck travels on highways, the secret to its hundreds of kilometers of range lies within its chassis and battery compartment. As the wave of heavy-duty truck electrification sweeps the global logistics industry, the layout and stacking technology of battery systems have become critical to market success.

Figure 1: Liquid Cooling Solution for Electric Heavy-Duty Truck Batteries

1-Battery Layout: How Three Solutions Reshape Electric Heavy-Duty Trucks?

a. Back-Mounted Layout: Agile Choice for Short-Distance Transport

· Scenario: Short-haul operations in enclosed areas like ports, mines, and steel plants.

· Core Advantage: Rapid battery swapping (specific times require validation), improving vehicle utilization.

· Limitations: Battery capacity constraints (<350 kWh industry standard), high center of gravity affecting stability.

· Space Trade-off: Occupies cargo or cabin space, reducing load capacity.

b. Chassis-Mounted Layout: Endurance King for Long-Haul Transport

· Capacity Breakthrough: Battery capacity exceeds 500 kWh (e.g., disclosed 513 kWh solutions).

· Space Efficiency: Maximizes chassis space, avoiding cargo encroachment.

· Safety: Ultra-low center of gravity enhances high-speed stability.

· Technical Barriers: Chassis integration demands higher protection and thermal management.

c. Bottom-Side-Mounted Layout: Efficiency Engine for Battery Swap Networks

· Innovation: Lateral battery swapping boosts operational efficiency.

· Space Balance: Preserves full cargo space, with range between back and chassis layouts.

· Safety Focus: Requires reinforced side-impact protection structures.

2-Stacking Technology: Efficient Integration Solutions for Truck Battery Packs

Multilayer stacking is key to improving energy density:

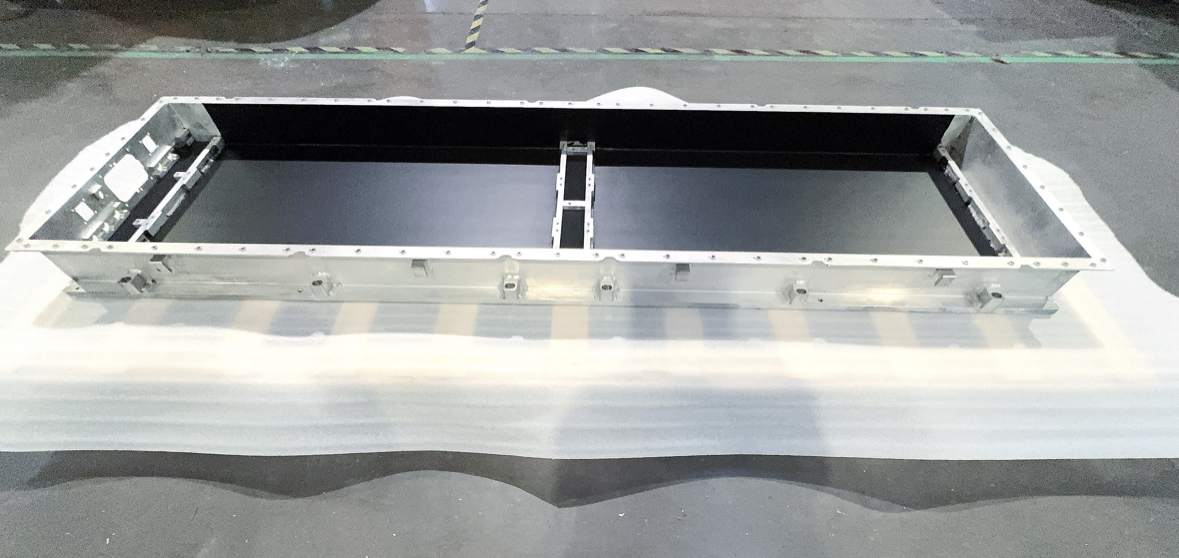

Figure 2: Stacked Liquid Cooling Integration Box for Heavy-Duty Trucks

a. Frameless Integrated Stacking:

· Direct cell stacking reduces structural components.

· Eliminates modules/frames, enabling "Seamless Z-Stacking".

· Significantly boosts system energy density.

· Supports ultra-fast charging (performance requires validation).

b. Module-to-Chassis Integration (e.g., MTB/CTC):

· MTB: Modules directly connect to the frame, improving volume utilization.

· Qilin Battery(CTP 3.0): 72% volume utilization, 255 Wh/kg energy density.

· CTC: Cells integrate into the chassis, reducing weight by 10%.

c. Cell Form Innovation (e.g., Blade Battery):

· Flat cells tightly arranged, increasing volume utilization (>50% per BYD data).

· Breaks LFP energy density bottlenecks.

3-Core Technical Challenges

Challenge 1: Structural Safety

· Extreme Conditions: Side-pole collisions threaten side-mounted layouts.

· Solutions: High-strength aluminum alloy housings + buffers; FEA collision simulation; super-national mechanical impact tests.

Challenge 2: Thermal Management

· Critical Issue: Temperature differential control within packs is vital.

· Innovations: Lateral liquid cooling(<3°C differential); direct refrigerant cooling; MPC dynamic control.

Challenge 3: Vibration Fatigue

· Hidden Risk: Road vibration causes structural damage.

· Strategies: Z-stacking optimizes stress distribution; road spectrum vibration testing; high-damping materials.

4-Current Development Trends

· Chassis-mounted layouts dominate medium/long-haul: High range (>500 kWh) and low center of gravity are preferred.

· CTC integration fuses batteries with chassis, improving space utilization and rigidity.

· AI-driven thermal management enables precise temperature control (<5°C differential), extending battery life.

· Semi-solid-state batteries accelerate commercialization, focusing on safety and energy density.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.