Communication and sharing promote growth

Joining Hands for Development!

When the "Large" Size of Battery Cells Becomes a Consensus, the "Strength" of the Pack Becomes the New Battleground

The energy storage industry is entering an era of leapfrogging battery cell capacities, with the shift from 280Ah towards 500Ah+ already underway. While the industry focuses on the "largeness" of cells, the "strength" of the Pack—specifically its mechanical structure's load-bearing and safety mitigation capabilities—is becoming the new competitive focus. Regardless of the evolution in cell chemistry and capacity, the resulting expansion forces, thermal runaway energy, and mechanical loads ultimately must be borne by the Pack's lower enclosure, its mechanical foundation.

From a structural design perspective, this article explores how the Pack lower enclosure can address differentiated mechanical and thermal management demands amidst diverging cell technology pathways, and build sustainably adaptable engineering capabilities.

1- Mechanical Analysis of Three Major Technology Paths: The Triangular Challenge of Load, Heat, and Space

The increase in cell capacity directly alters the boundary conditions for Pack system design. As the "skeleton" and "skin" of the system, the lower enclosure must re-address three fundamental questions:

a. Mechanical Analysis for the 587Ah (High-Integration Path)

Core Demand: Achieving energy density ≥6MWh within a standard 20-foot container has spurred ultra-compact layouts like "4 columns, 8 clusters in total."

Lower Enclosure Challenges:

· Structural Load-Bearing Optimization: With increased overall mass but reduced support points, the enclosure must optimize load transfer paths, balancing overall stiffness with local strength in critical areas to ensure structural stability during transportation and operation.

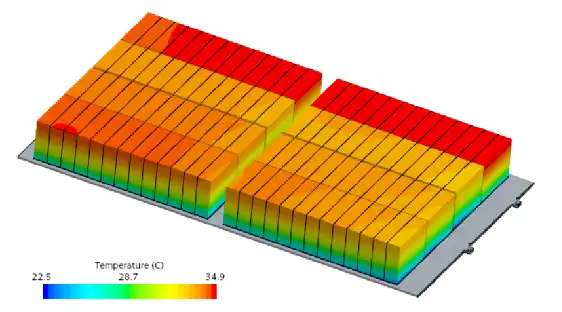

· Integration of Thermal Management Structure: The liquid cooling system is deeply integrated with the enclosure's base plate and support structures, serving both as the thermal management core and participating in overall load-bearing. The design must ensure the long-term reliability of cooling seals under sustained structural loads and thermal cycling.

Simulation of Energy Storage Pack Lower Enclosure

· Precise Spatial Coordination: The enclosure must allocate reasonable clearances within the limited space for cell expansion, thermal displacement of electrical connections, fire suppression piping, etc., enabling the reliable coexistence of all subsystems within the compact layout.

b. Thermo-Mechanical and Structural Response Analysis for the 684Ah (Ultra-Large Capacity Path)

Core Demand: Minimizing cost per Wh by maximizing single-cell capacity, which introduces physical centralization effects.

Lower Enclosure Challenges:

· "Focal Point" Effect of Expansion Force: The expansion force of a single cell does not increase linearly with capacity but nearly exponentially. The internal frame of the enclosure requires a more robust and uniform "restraint system" to distribute the concentrated expansion stress across the entire structure, avoiding local plastic deformation.

· "Uniformity" Dilemma in Thermal Management: Larger heat-generating bodies require more efficient heat conduction paths. The material, thickness of the enclosure's base plate, and the design of the contact interface with the cell bottom (such as the compression ratio setting for thermal pads) become critically important. During thermal runaway, the larger energy release places higher demands on the directional venting capability of pressure relief channels and the flame-retardant duration of internal fire barriers.

· Structural Response to Concentrated Weight: Heavier individual cells alter the overall vibration modes of the Pack. The lower enclosure requires renewed fatigue simulation to prevent resonance at specific frequencies leading to fastener loosening or structural cracks.

c. Manufacturing Adaptability Explanation for the 392Ah (Robust Transition Path)

Core Demand: Focuses on balancing performance, cost, and delivery efficiency, providing a thoroughly validated solution to the market.

Lower Enclosure Challenges:

· Stable Realization of Mature Solutions: Ensuring product consistency through strict process control based on a verified design and manufacturing system, supporting rapid and stable mass production schedules.

· Deep Supply Chain Collaboration: Leveraging an established supply system to continuously enhance the product's comprehensive cost competitiveness through material selection, process optimization, and scaled procurement.

2- Engineering Thinking to Address Divergence

Confronted with multiple technology pathways, lower enclosure suppliers cannot rebuild their technical systems for each path. The real solution lies in platform-based, precise response—efficiently adapting to different requirements through scalable, modular design.

a. Focusing on Common Physical Principles and Collaborative Models

Cell iteration follows stable physical laws. We have established a collaborative evaluation process based on core parameters, integrating materials and structural data to rapidly assess the feasibility of new cells. This enables early identification of matching risks, helping to converge design directions and reduce late-stage iterations.

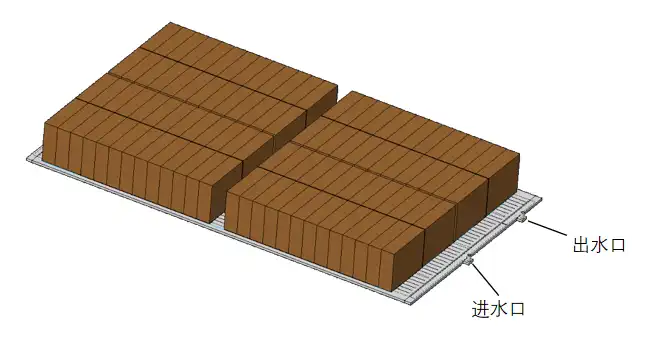

587Ah Energy Storage Battery Pack Lower Chassis

b. Building a Flexible System of "Standardized Interfaces + Configurable Modules"

To address the customization demands arising from technological divergence, we have established a design system with clearly defined interface standardization and internally configurable modules:

· Unified External Interfaces: Installation positioning to the energy storage container, electrical penetration interfaces, cooling system connection points, etc., all strictly adhere to common industry specifications, ensuring compatibility and assembly consistency at the system level.

· Configurable Internal Structure: We offer a series of internal support components and thermal management integration solutions that can be flexibly combined according to cell dimensions and layout.

· Thermal Management Integration Module: The thermal management module adopts a modular design, focusing on optimizing temperature rise control and cell temperature uniformity. It can flexibly adapt to the thermal management needs of different technology paths.

c. Implementing Flexible Production Lines with "Design for Manufacturability"

To match the diversity of technology paths, our manufacturing system is organized around an extensible base platform and modular assembly:

· Base Enclosure Platform Manufacturing: Ensures the precision and consistency of the main structure, providing a reliable carrier for different configurations.

· Modular Assembly Units: Supports flexible selection and assembly of corresponding internal support and thermal management modules based on cell size and layout. Through this setup, we can efficiently switch production for products of different technology paths on the same line, assisting customers in managing supply chain and delivery challenges posed by parallel multi-path development.

3- Redefining the Value of the Lower Enclosure: From Passive Bearing to Active Enablement

The lower enclosure is transitioning from a passive container to a critical system-enabling component, directly impacting safety, energy density, and total lifecycle cost:

a. Safety-Critical Load-Bearing Structure: By providing reliable structural channels and mounting foundations for system-level pressure relief and fire barriers, it works in concert with thermal runaway propagation control to build multi-tiered safety protection.

b. Energy Density Enabler: Lightweight, high-strength design reduces its own weight and spatial footprint, reserving more performance margin for the battery cells and cooling system.

c. Long-Term Reliability Assurance: Structural integrity and fatigue endurance design support the system in withstanding continuous challenges like long-term cycling and transportation vibrations.

4- Conclusion: Building a Bridge Between Diverging Upstream and a Determined Downstream

As battery cell technology evolves, energy storage systems relentlessly pursue safety, high density, and low cost. The lower enclosure must provide a reliable and adaptable foundational support, utilizing modularity and flexible manufacturing to accommodate different technology pathways. Industry competition is shifting towards system-level engineering, where the Pack enclosure serves as a pivotal link.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.