Communication and sharing promote growth

Joining Hands for Development!

The wave of electric heavy-duty trucks is sweeping across the global logistics and transportation industry, injecting strong momentum into the "dual-carbon" goals. However, with the soaring demand for extended range, battery systems with single-pack capacities exceeding 500kWh or even approaching 1000kWh have become commonplace. This is akin to equipping vehicles with a mobile "energy fortress," but the potential thermal safety risks have also reached unprecedented levels. When the three extreme safety indicators—"ultra-large capacity," "ultra-fast thermal propagation" (<2 minutes), and "ultra-high collision resistance" (>1500kJ)—converge, the industry faces a severe technological gap. This article analyzes these challenges and explores systematic solutions to build a dedicated safety defense line for electric heavy-duty trucks.

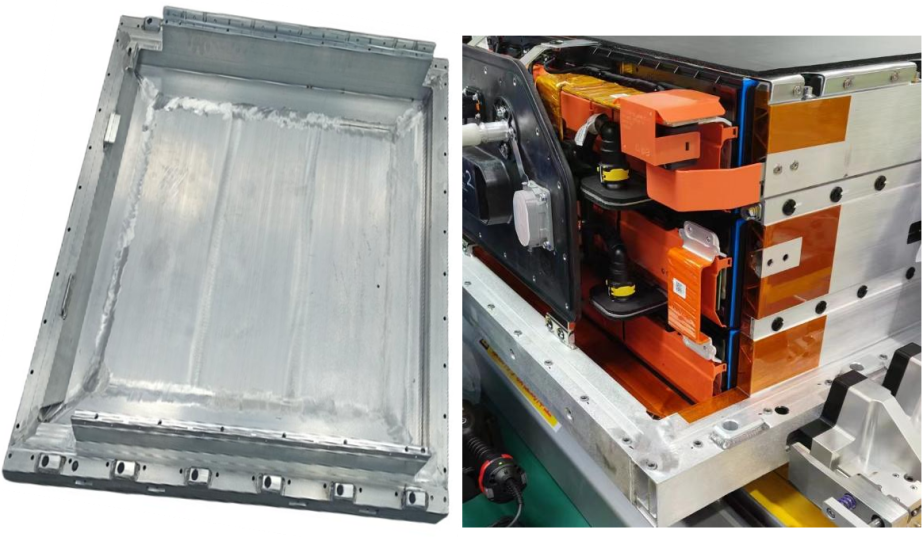

Figure 1: Short-Blade Three-Layer Stacking Solution

1-The 500kWh+ Era: Opportunities and Safety Challenges Coexist

a. Capacity Leap Has Become the Norm

To meet the demands of heavy-load, long-distance transportation, the battery capacity of electric heavy-duty trucks has rapidly increased from 200-300kWh to 600kWh+. Industry leaders have rolled out solutions ranging from 500kWh and 600kWh to even 1000kWh, marking the official arrival of the ultra-large-capacity era.

b. The Maturity of LFP (Lithium Iron Phosphate) Battery Technology

LFP batteries have become a major driver due to their advantages in safety and cycle life, making them the mainstream choice for heavy-duty trucks.

2-The "Three Major Challenges" Under Extreme Safety Demands

a. Thermal Propagation Limit Control (<2 Minutes)

· Core Objective: Safety designs must delay or block thermal propagation to create a time window for evacuation and rescue (e.g., the 5-minute early warning requirement under China's GB 38031-2020 standard).

· Harsh Reality: In high-density battery packs exceeding 500kWh, the massive energy released by a single cell during thermal runaway can easily trigger a catastrophic chain reaction. Test data shows extremely rapid thermal propagation: in some cases, it takes only 22 seconds to engulf the entire pack, 5 seconds to ignite adjacent modules, and as little as 44 seconds for inter-module propagation.

· Core Difficulty & Gap: How to effectively ensure inter-module thermal propagation is controlled beyond 2 minutes? Currently, no commercial heavy-duty truck system has publicly claimed or verified compliance with this stringent requirement.

b. Structural Collision Resistance Barrier (>1500kJ)

· Core Requirement: The collision energy of a fully loaded heavy-duty truck far exceeds that of passenger vehicles, easily surpassing 1500kJ. As a structural component of the chassis, the battery pack must possess ultra-high strength to remain intact post-collision, preventing internal cell damage that could lead to thermal runaway.

· Harsh Reality: Current domestic and international standards (e.g., GB/T 31467.3-2015, UNECE R100) lack clear or sufficient thresholds for collision energy testing of heavy-duty truck battery packs. Publicly available certification data for systems passing 1500kJ-level collision tests is extremely scarce. Although higher-energy simulations exist (e.g.,2500kJ), full-system validation remains a significant challenge.

· Core Difficulty & Gap: The absence of clear high-energy collision protection standards and thoroughly validated solutions.

c. Secondary Disaster Chain Risks (Cargo Explosion & Road Paralysis)

· Cargo Explosion Risk: High-temperature flames from battery thermal runaway can easily ignite cargo (especially hazardous materials), forming a disaster chain: "battery runaway → cargo fire → explosion."

· Road Paralysis Risk: Lithium battery fires are difficult to extinguish (requiring large volumes of continuous cooling water) and prone to reignition. A multi-ton heavy-duty truck catching fire on a highway or in a tunnel complicates rescue efforts (high-voltage power cutoff, toxic gas prevention) and takes an extended time (up to several hours, with potential impacts lasting 24 hours), severely disrupting traffic and causing significant societal repercussions.

· Core Difficulty & Gap: The lack of targeted quantitative road clearance time standards and efficient emergency response systems.

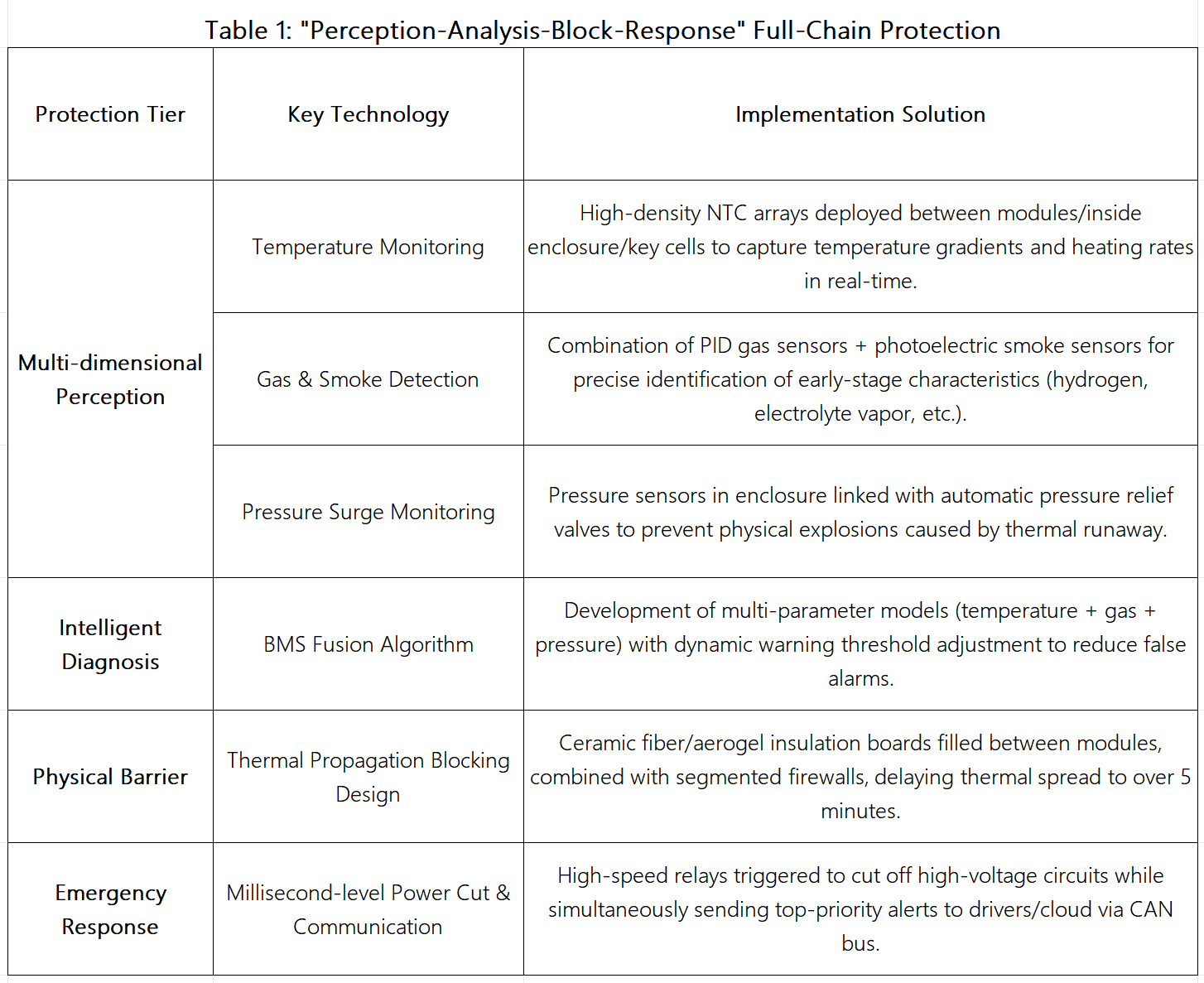

3-Building the Defense Line: Thermal Event Early Warning System Design – Four-Layer Protection Net

4-Thermal Management Supporting Solutions: Empowering the Early Warning System

· Liquid Cooling System: Integrated high-efficiency liquid cooling plates eliminate localized hotspots, maintaining a temperature difference of <3°C between cells.

· Modular Design: Independently detachable module structures enable quick replacement of faulty units.

· Intelligent Monitoring Platform: Cloud-based real-time battery health analysis with automatic early warning alerts sent to maintenance teams.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.