Communication and sharing promote growth

Joining Hands for Development!

In the new energy heavy truck market, "battery stacking" has become a key term: mainstream models now exceed 370kWh in battery capacity, with 600kWh+ models frequently debuting. This is not just a leap in technical specifications but also the industry's declaration of a full-scale assault on the line-haul logistics market—by enhancing single-charge range, addressing the core user pain point of "range anxiety," and optimizing total cost of ownership (TCO). This article will dissect the business logic and technological breakthroughs behind this trend.

1-Business Logic: Why Must We "Stack Batteries"?

a. Scenario-Driven Necessity

·Closed Scenarios (Short-Distance, High-Frequency): Ports, mines, and similar settings rely on battery-swapping models (3-5 minute recharge), where 280kWh batteries suffice.

·Line-Haul Logistics (Long-Distance Transport): Accounts for 70% of freight volume, requiring a single-charge range of 500+ km. 600kWh+ batteries serve as the "gateway" to this market.

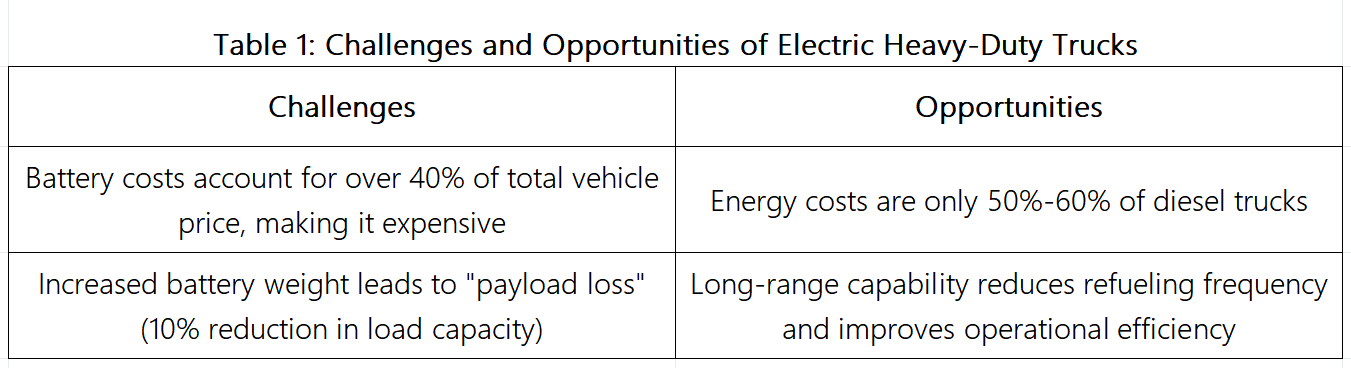

b. The Economics of TCO

Key Conclusion: When daily mileage exceeds 300 km, the TCO of battery-swap heavy trucks begins to outperform diesel trucks.

b. Model Innovation: Resolving Cost Challenges

·Battery-as-a-Service (BaaS): Users purchase the "bare vehicle" with battery leased monthly (¥5,000–9,000), reducing upfront costs by 30%.

·Battery Swap Services: Service fee of ¥0.2–0.5 per kWh, with total energy costs around ¥2.73/km (close to diesel trucks at ¥2.8/km).

·Commercial Validation: A swap station serving 50 vehicles/day can shorten the payback period to 5 years (IRR of 13.1%).

2-Technological Breakthroughs: How to Balance Range and Weight?

a. Spatial Compromise: Chassis for Space

·To prevent batteries from encroaching cargo space, the industry is optimizing battery layout. For example, integrating batteries into the chassis (replacing traditional rear-mounted designs) frees up cargo volume, lowers the center of gravity, and may improve energy efficiency.

·Trade-off: Reduced ground clearance and compromised chassis modularity.

b. Material Science Compromise: Energy Density for Weight

·The key to weight reduction lies in improving battery energy density (more energy stored per unit weight). Higher density enables lighter batteries or extended range at the same weight.

·Core Innovation: Battery materials (e.g., high-nickel cathodes, silicon-carbon anodes).

·Trade-off: Higher energy density often comes with safety risks, shorter lifespan, increased costs, and reduced fast-charging capability—requiring difficult multi-parameter balancing.

c. Business Model Compromise: Network Over Single-Vehicle Pressure

·The battery-swap model shifts the "infinite range" burden from individual vehicles to the swap network. By deploying dense swap stations along routes, trucks only need enough charge to reach the next station, eliminating oversized batteries.

·Outcome: Reduces extreme battery capacity demands, making onboard battery loads more "rational."

d. Residual Value Management: The Core Barrier for BaaS

Battery banks must develop full lifecycle capabilities: State-of-Health (SOH) monitoring, cascading reuse, and recycling systems.

Figure 1: Heavy-duty truck battery pack enclosure

3-Future Trends: From "Battery Stacking" to "Efficient Energy Loading"

a. Technology Evolution: Solid-state batteries will break energy density barriers, rebalancing weight and range.

b. Charging Infrastructure: Standardized heavy-truck swapping protocols and grid synergy (e.g., peak shaving) are critical for scale.

c. Multi-Path Competition: Hydrogen-powered heavy trucks retain substitution potential in long-haul, heavy-load segments.

Conclusion: Phased Strategy, Long-term Evolution

"Battery stacking" is an inevitable choice for electric heavy trucks to conquer line-haul logistics, reflecting a dynamic balance between commercial needs and technical realities. As battery technology advances and business models mature, the industry will shift from a "capacity race" to an "efficiency race." Currently, it is driving China's new energy heavy trucks to complete the critical leap from "niche" to "mainstream."

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.